Reliable industrial quality

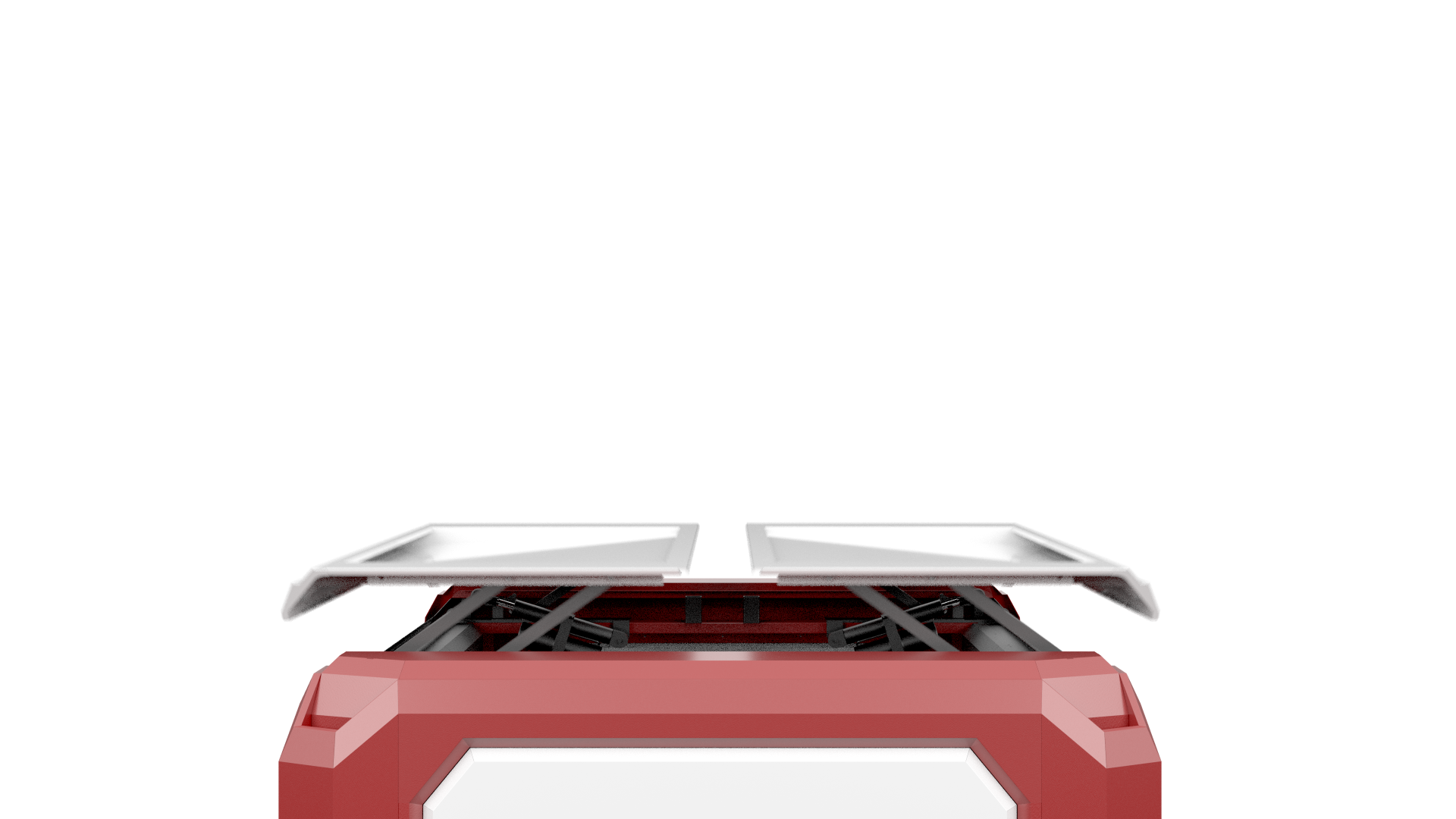

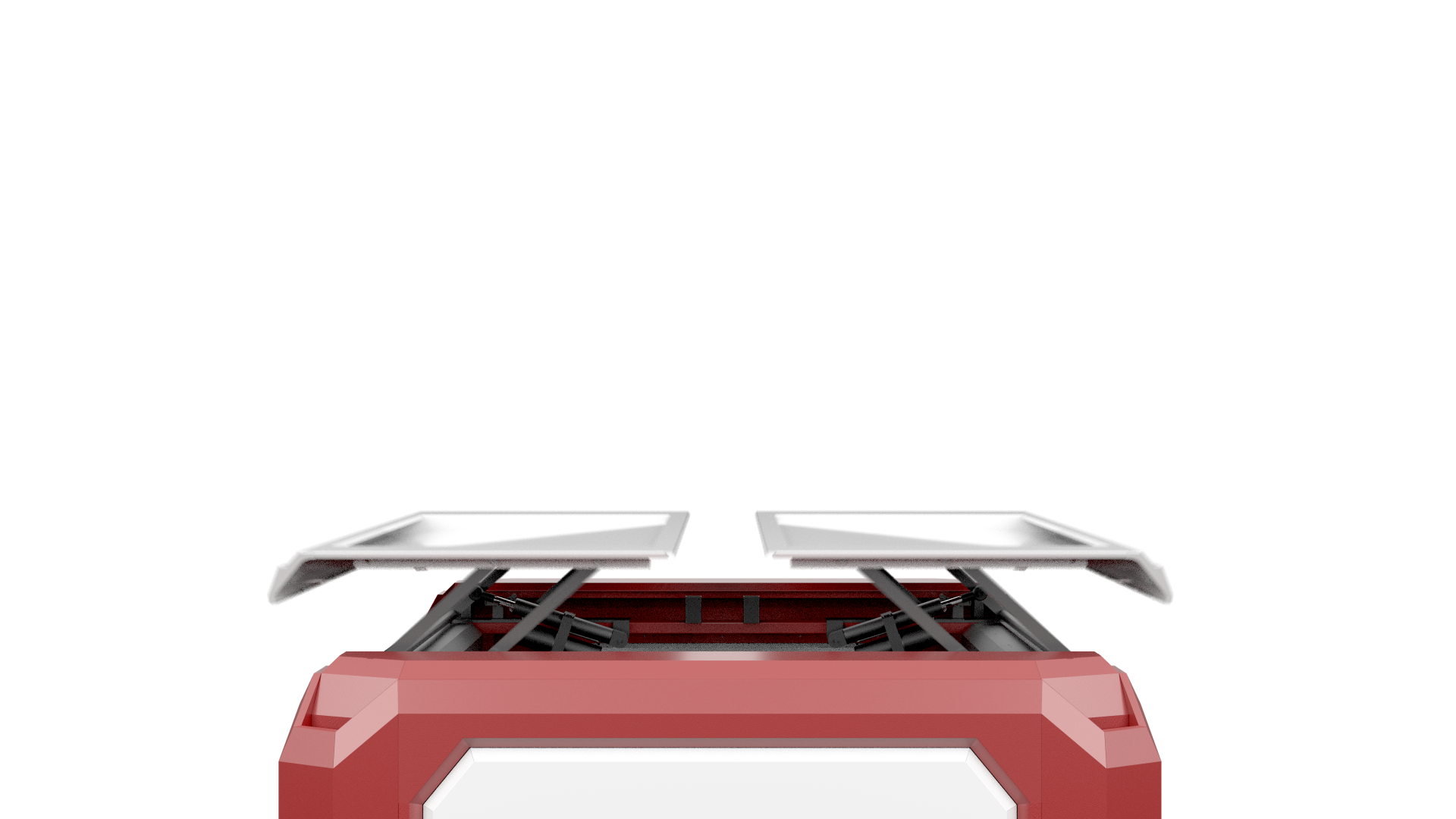

The industrial protection level of “Tiger dens” can reach IP55, with constant temperature and drainage system.

And coordinated with the micro-meteorological system, strong security protection is ready in industrial scenarios for the airport system and drones.

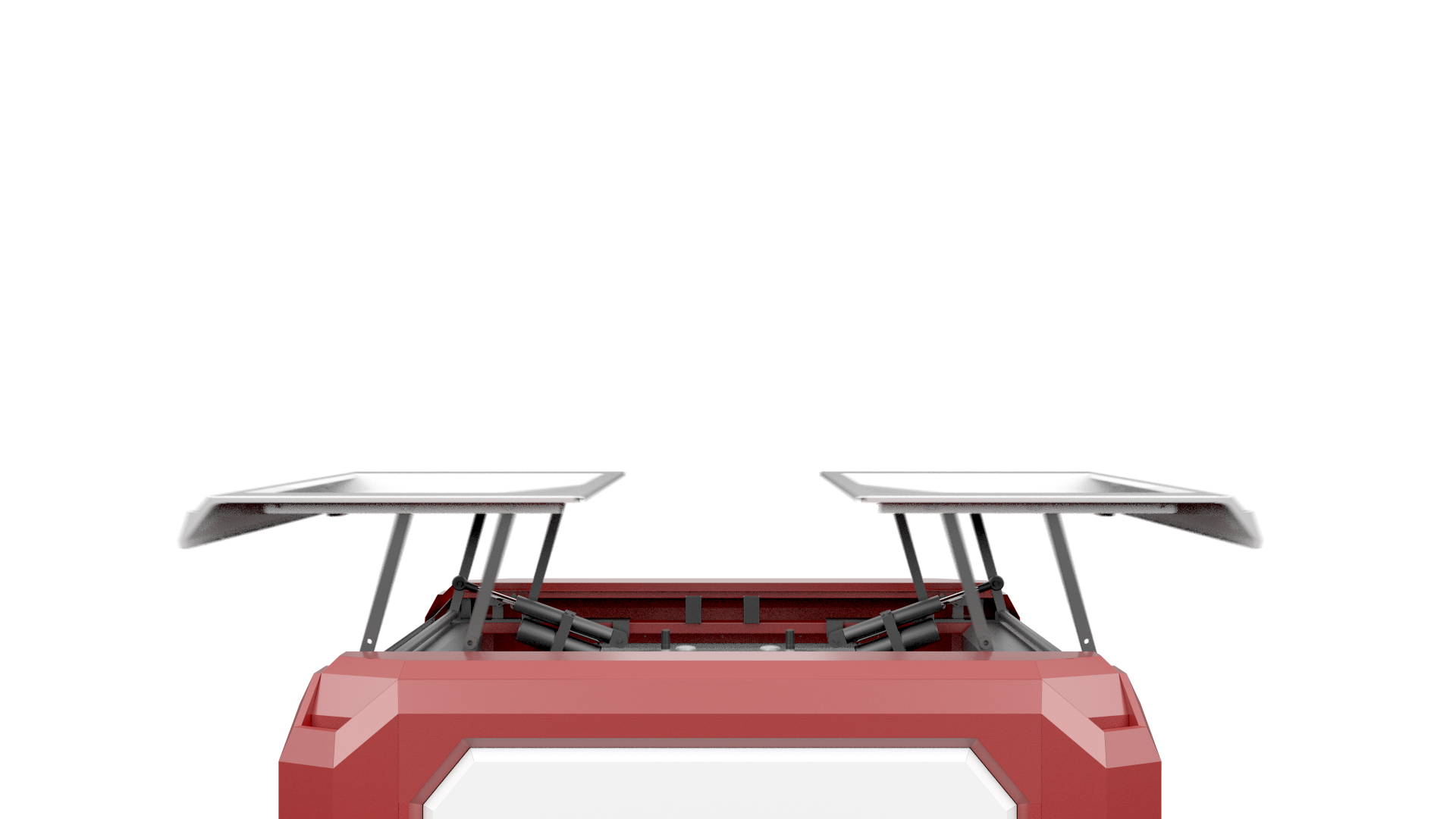

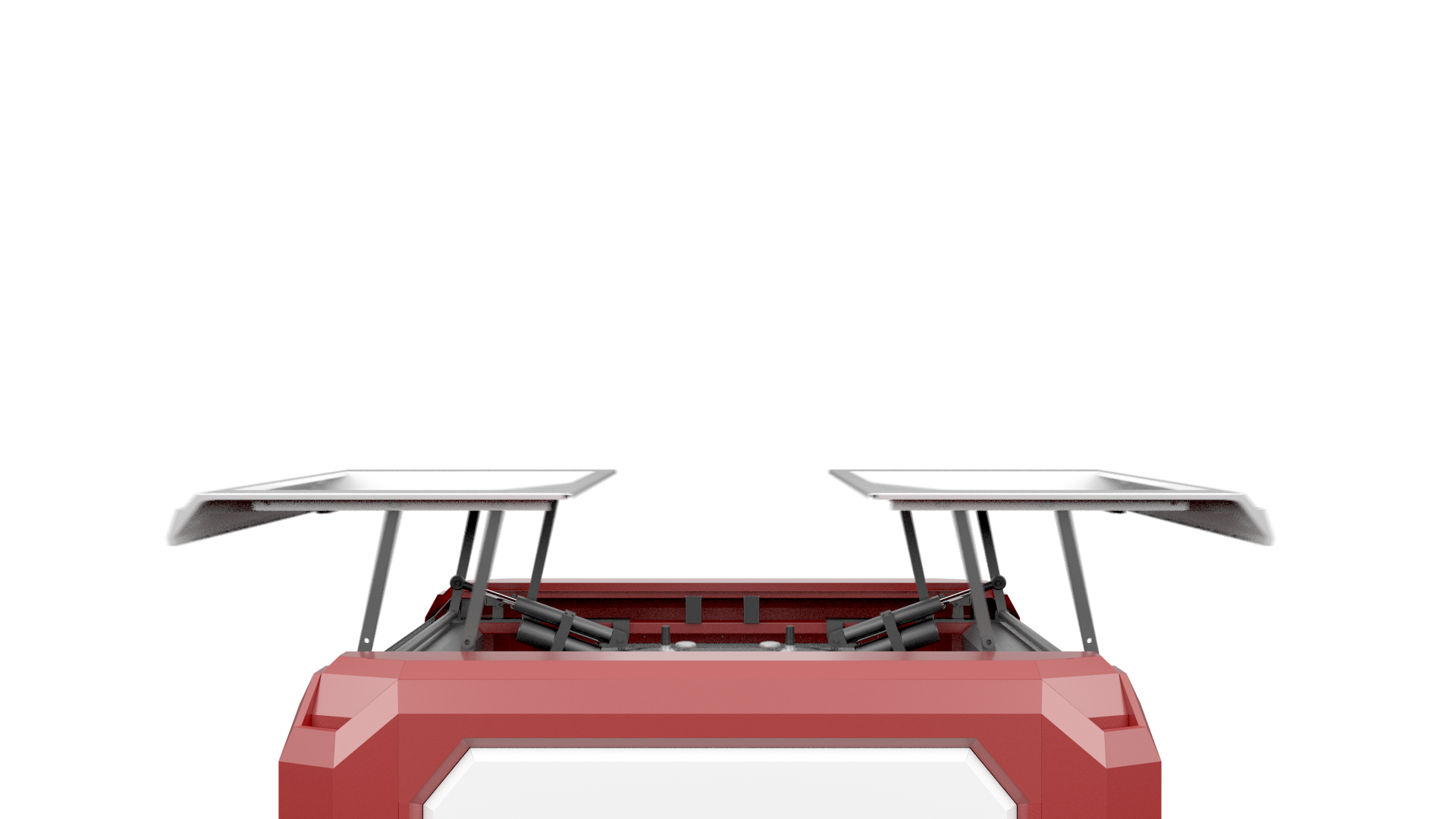

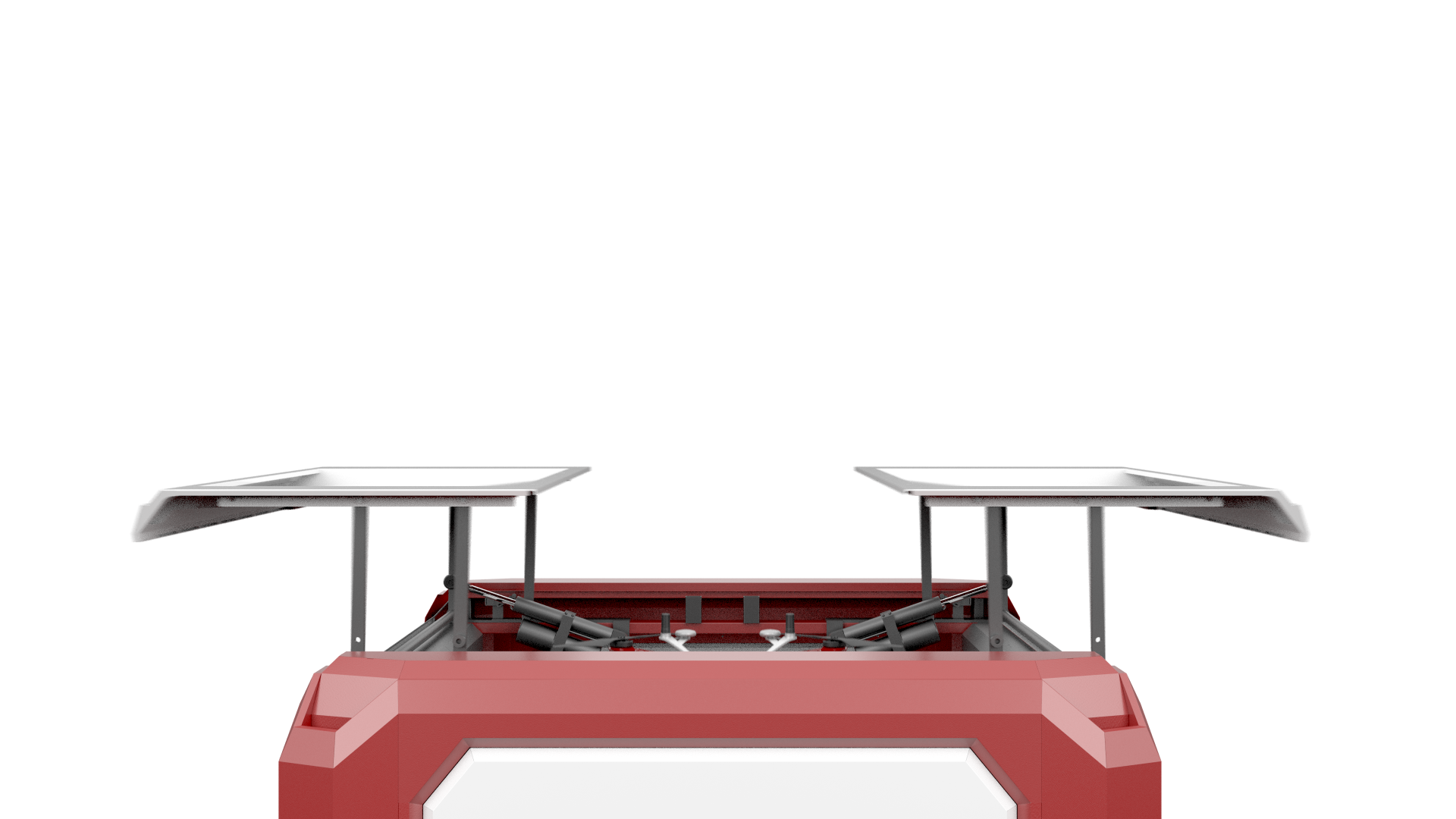

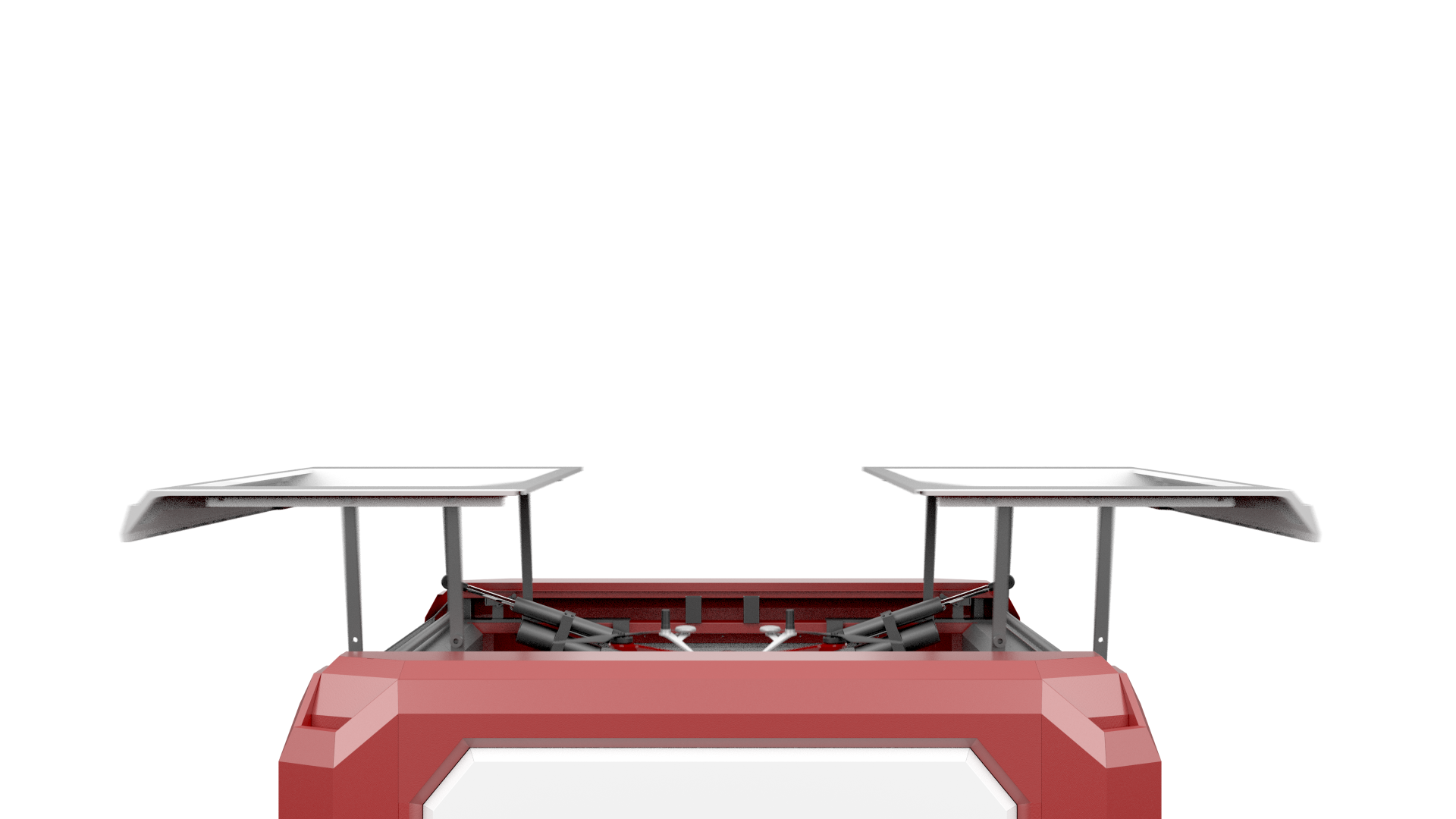

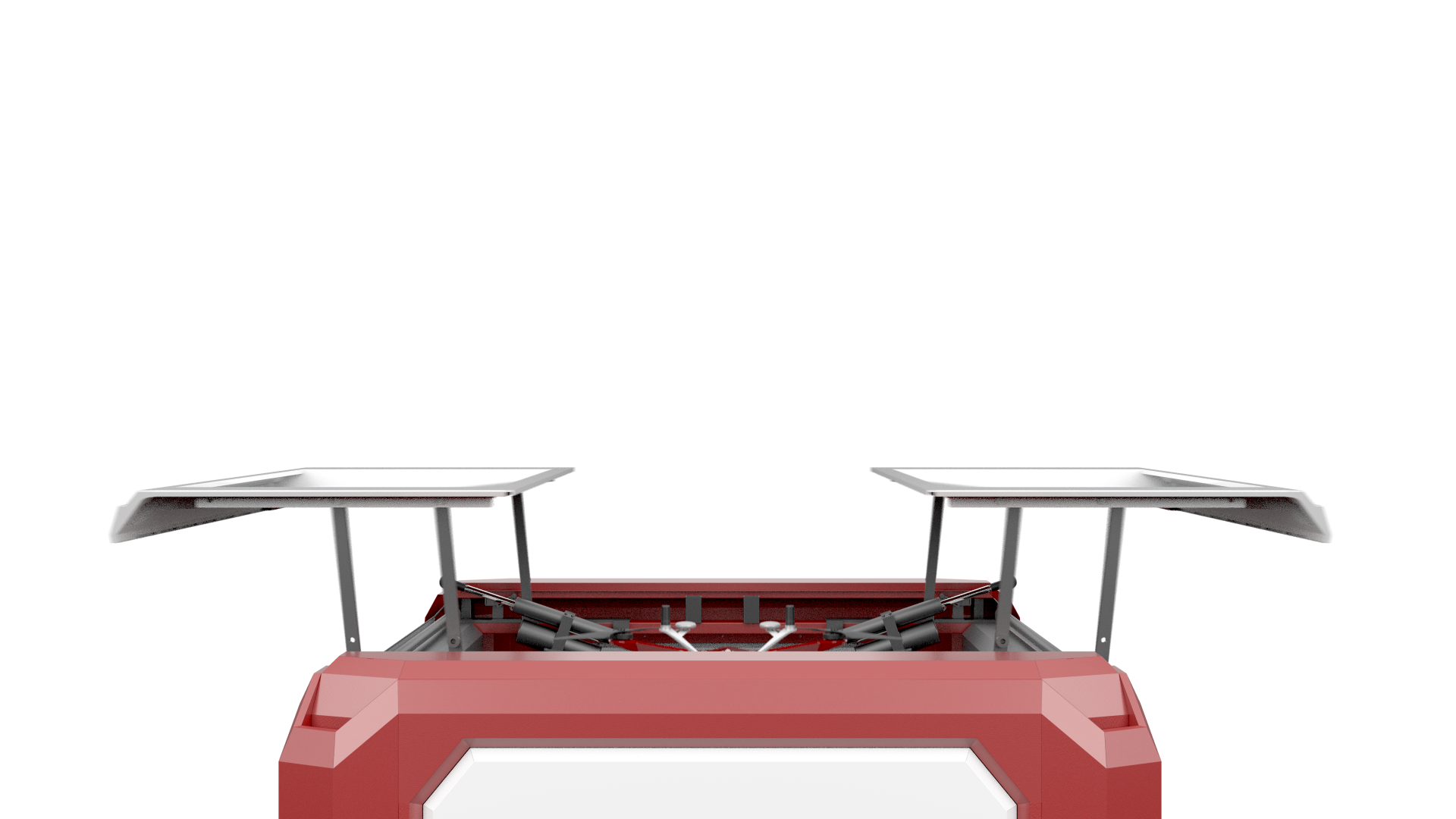

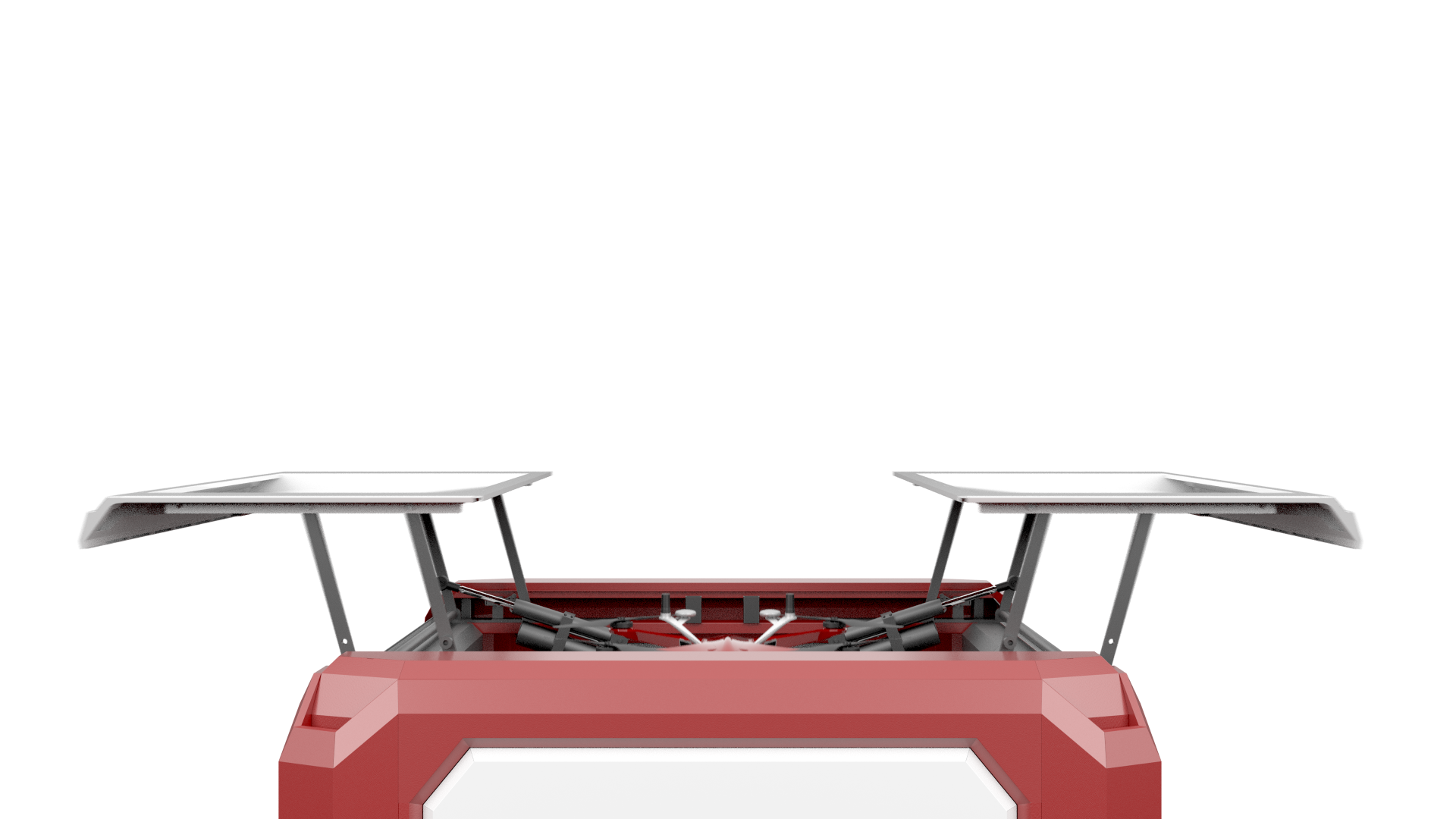

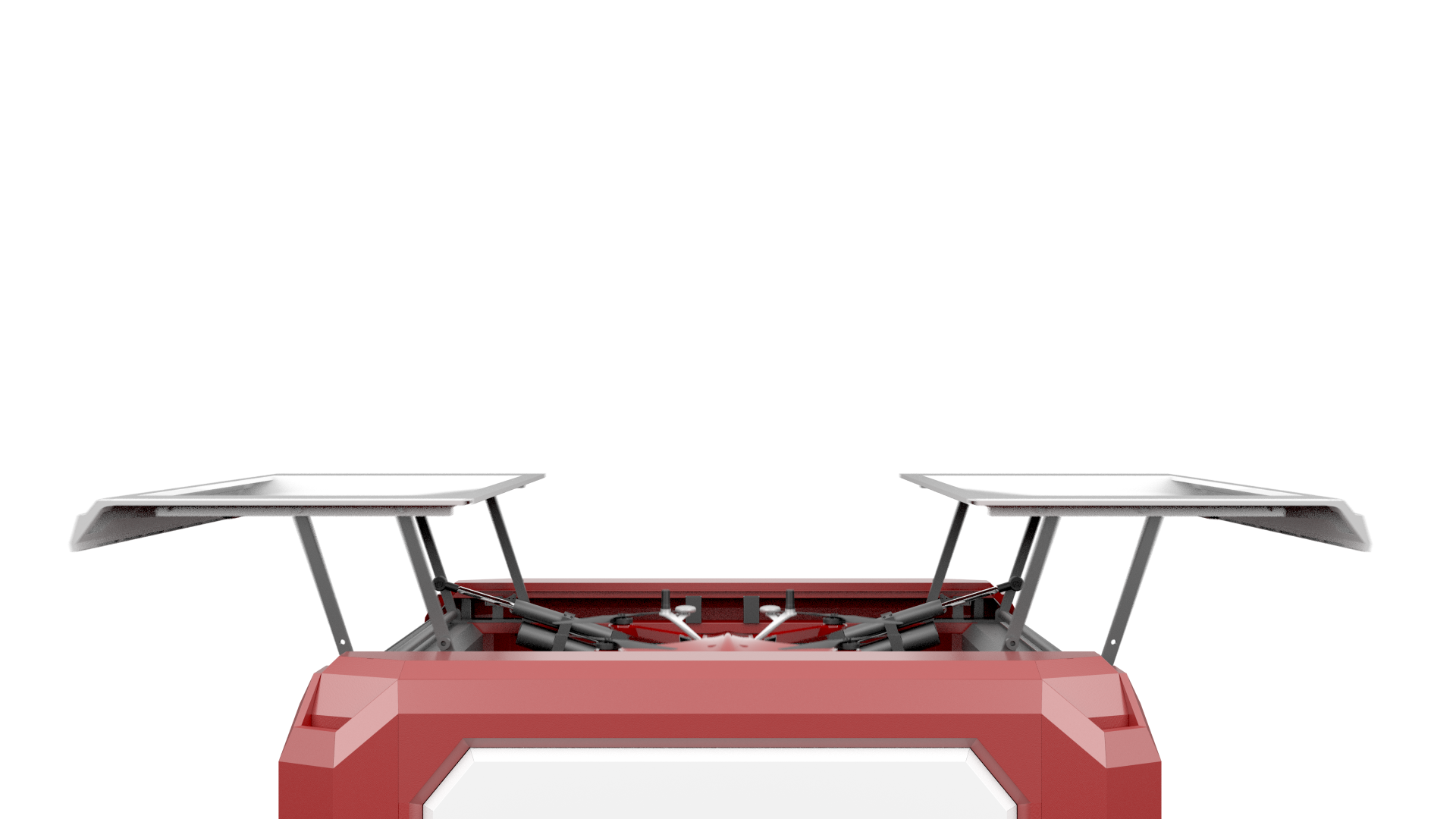

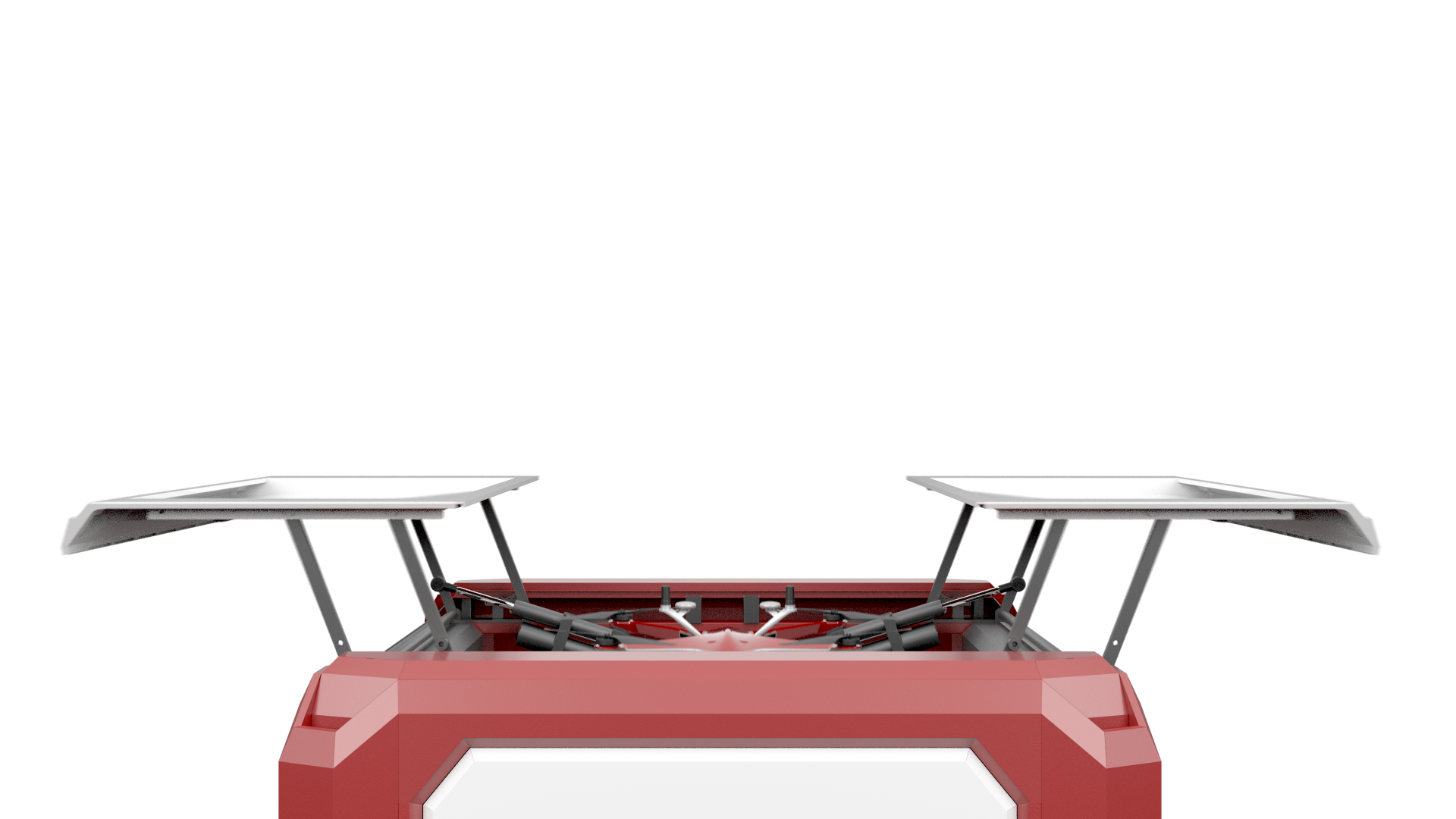

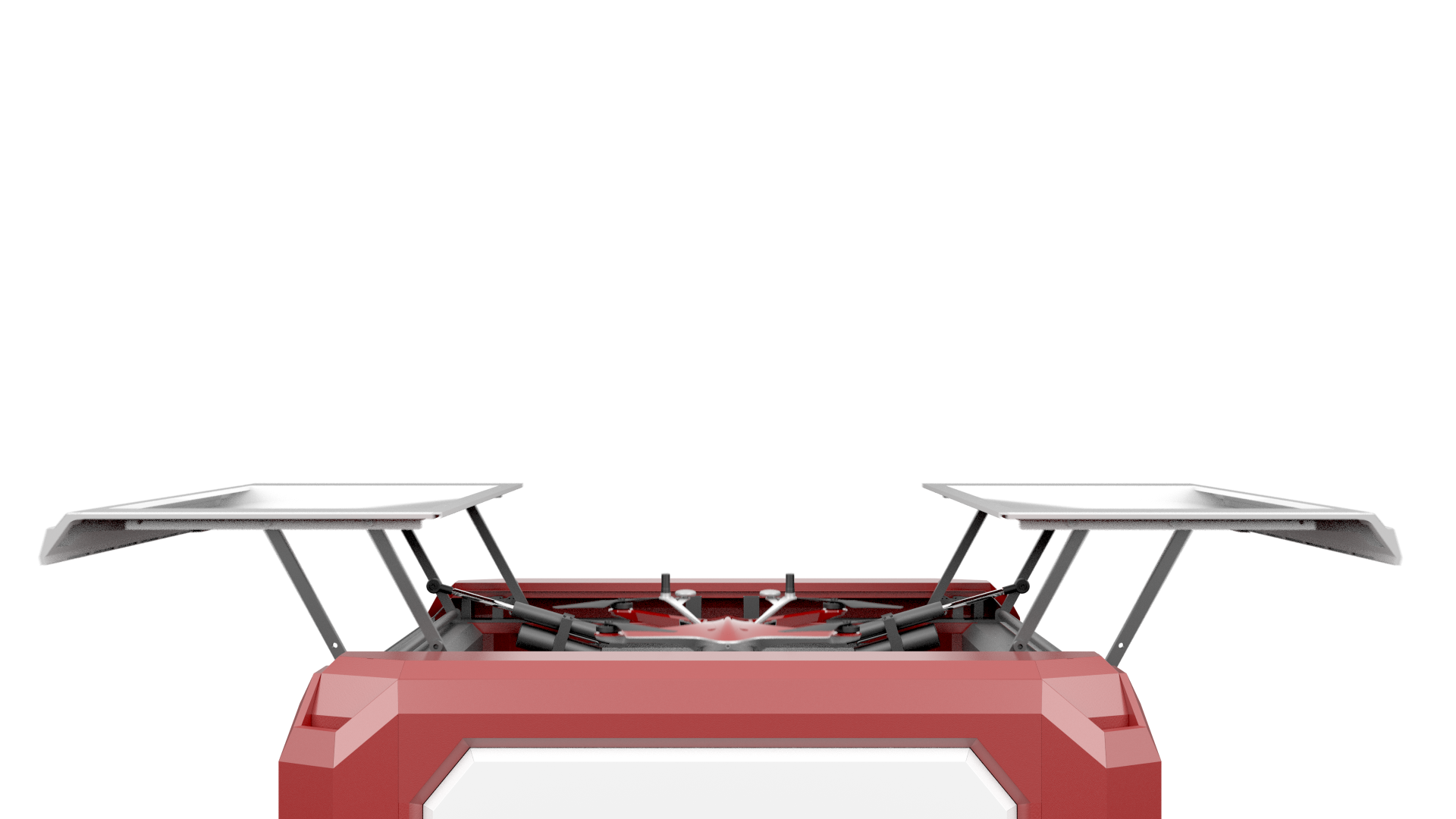

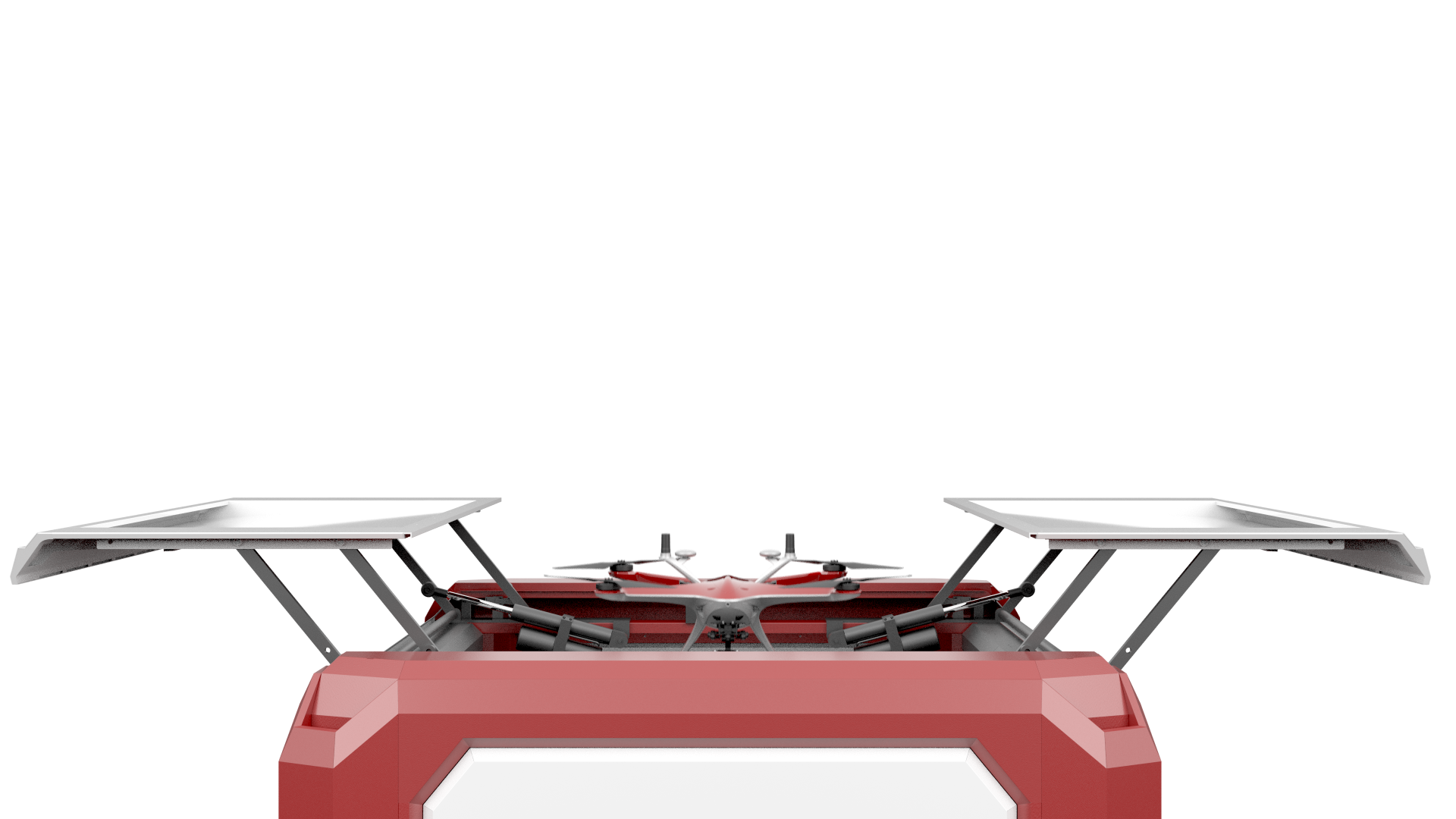

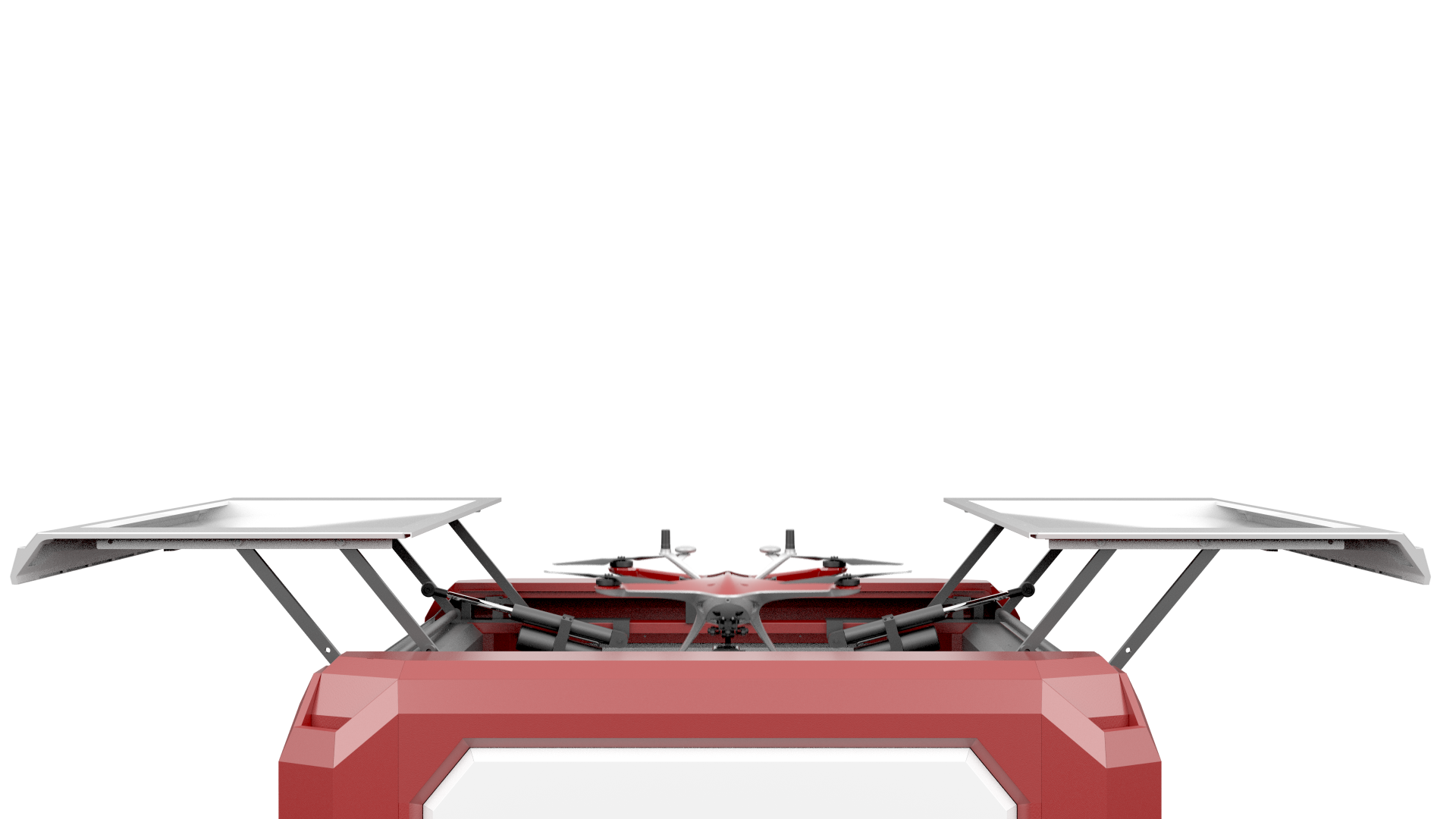

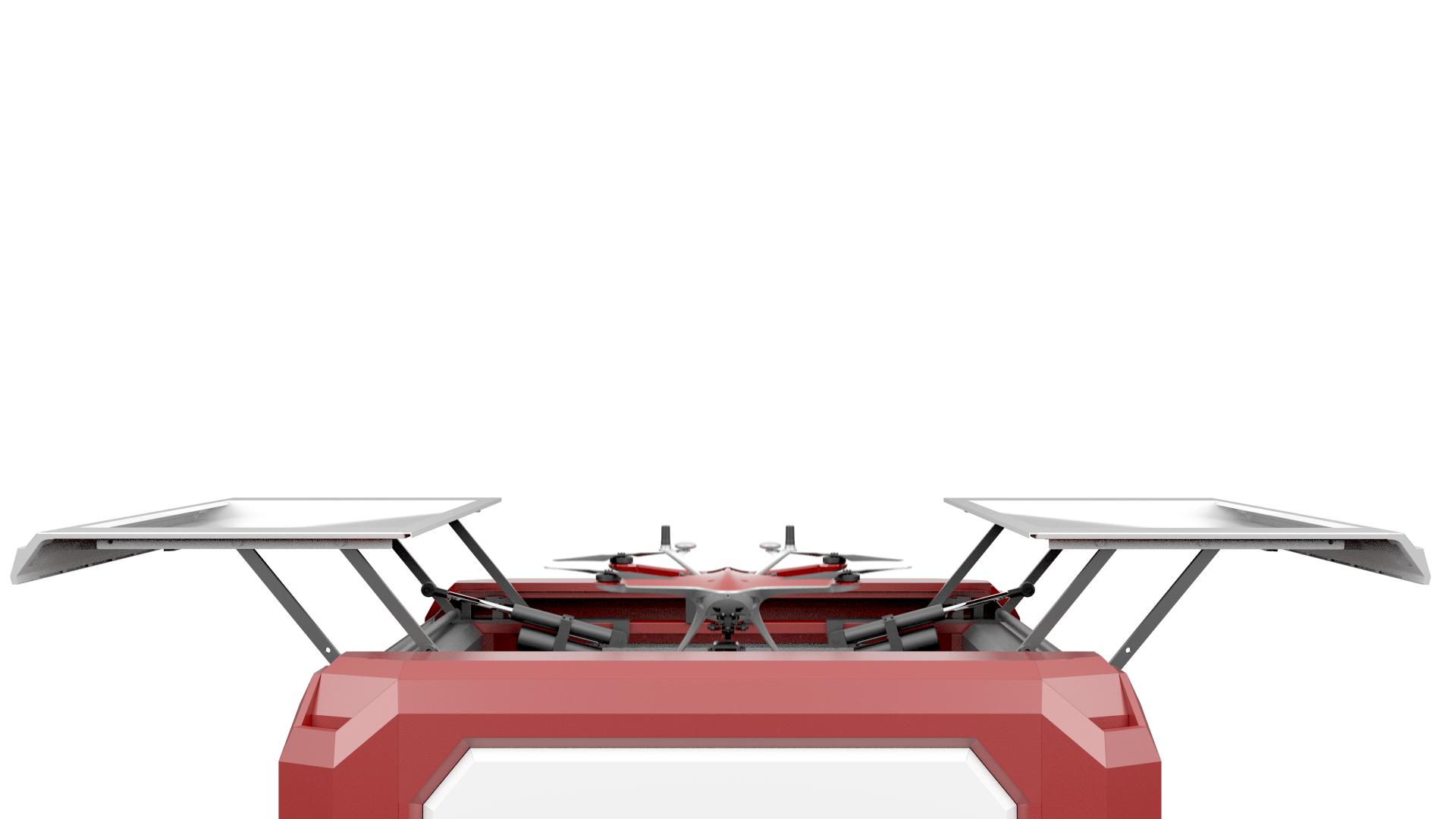

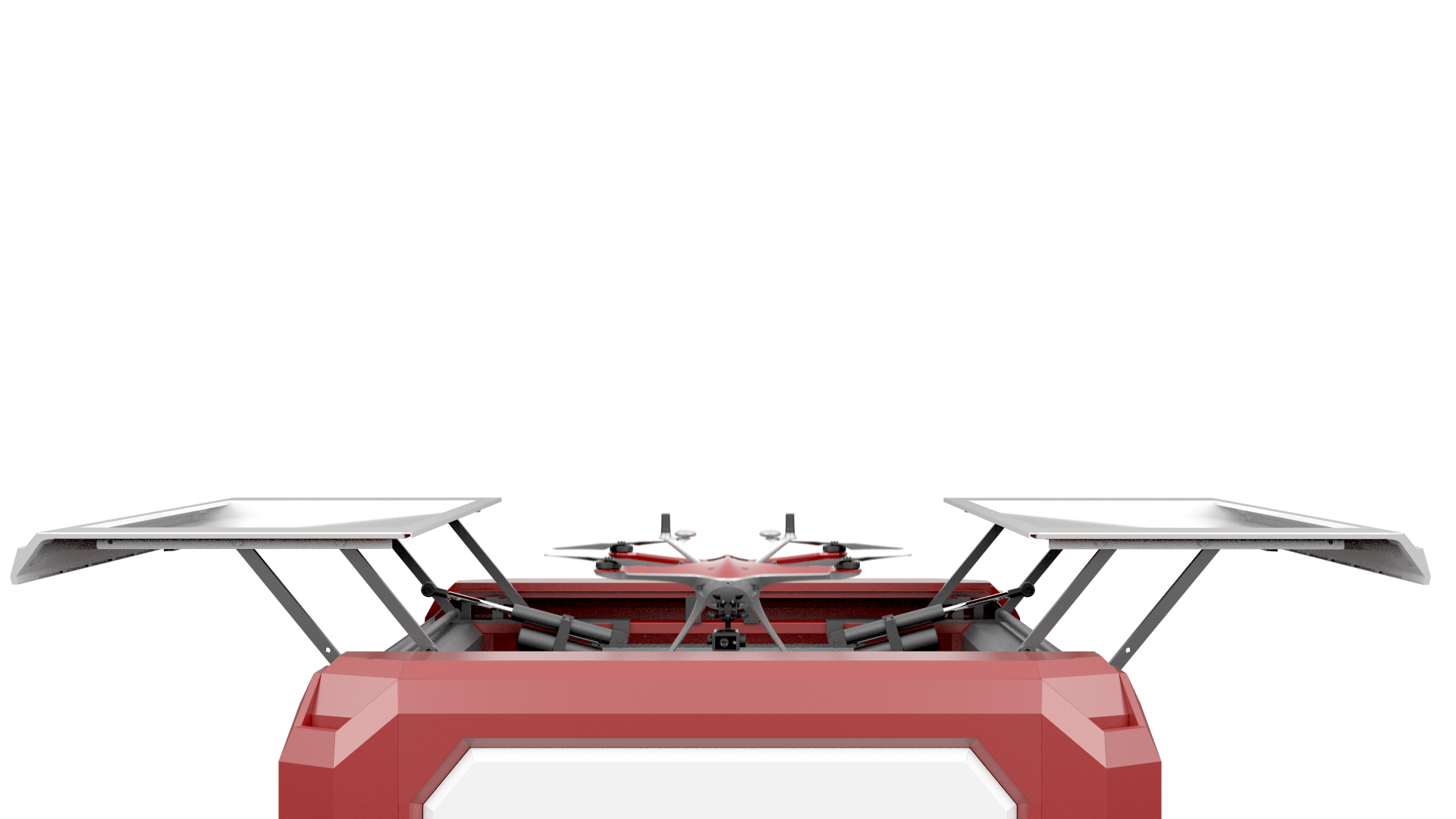

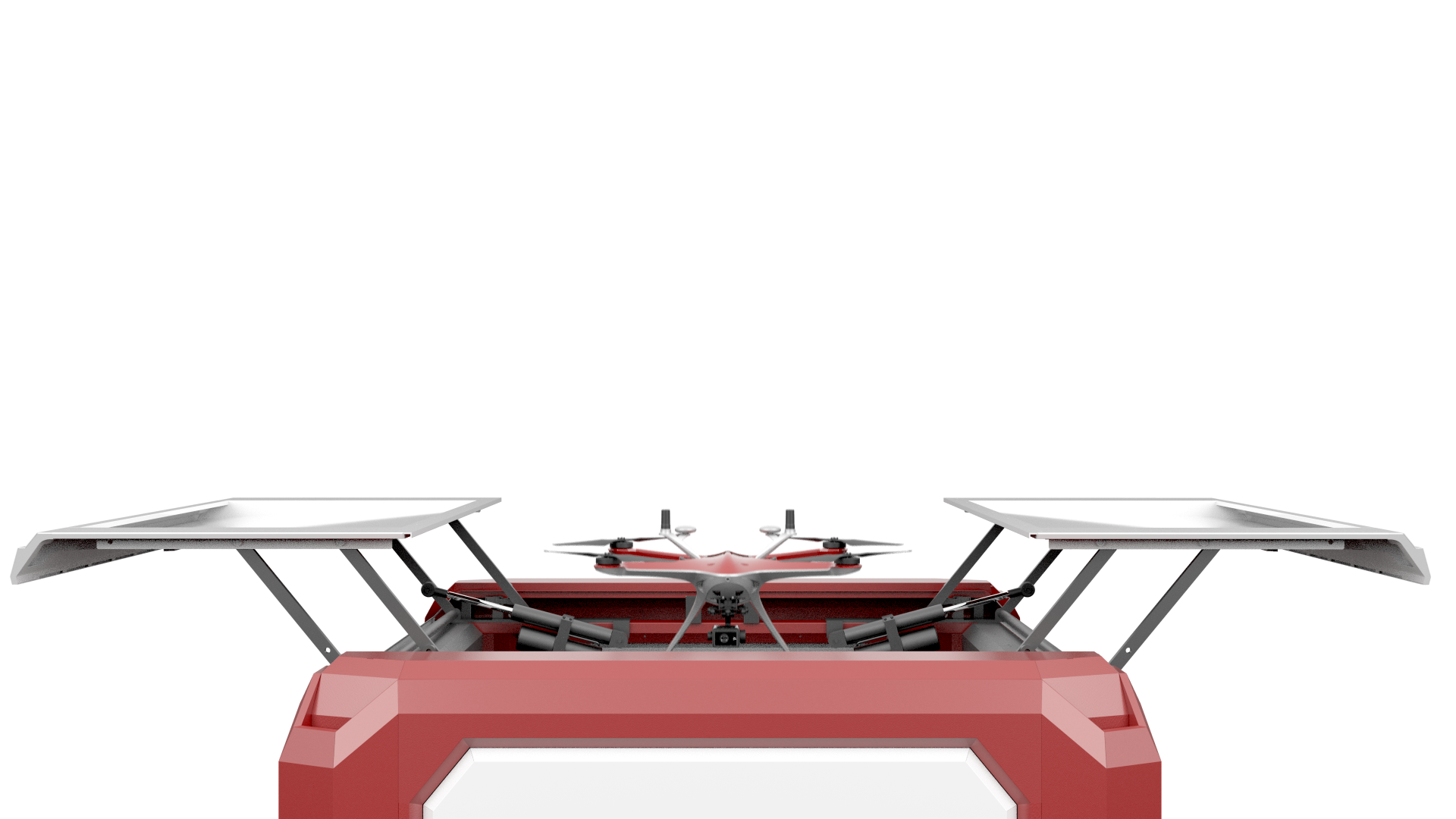

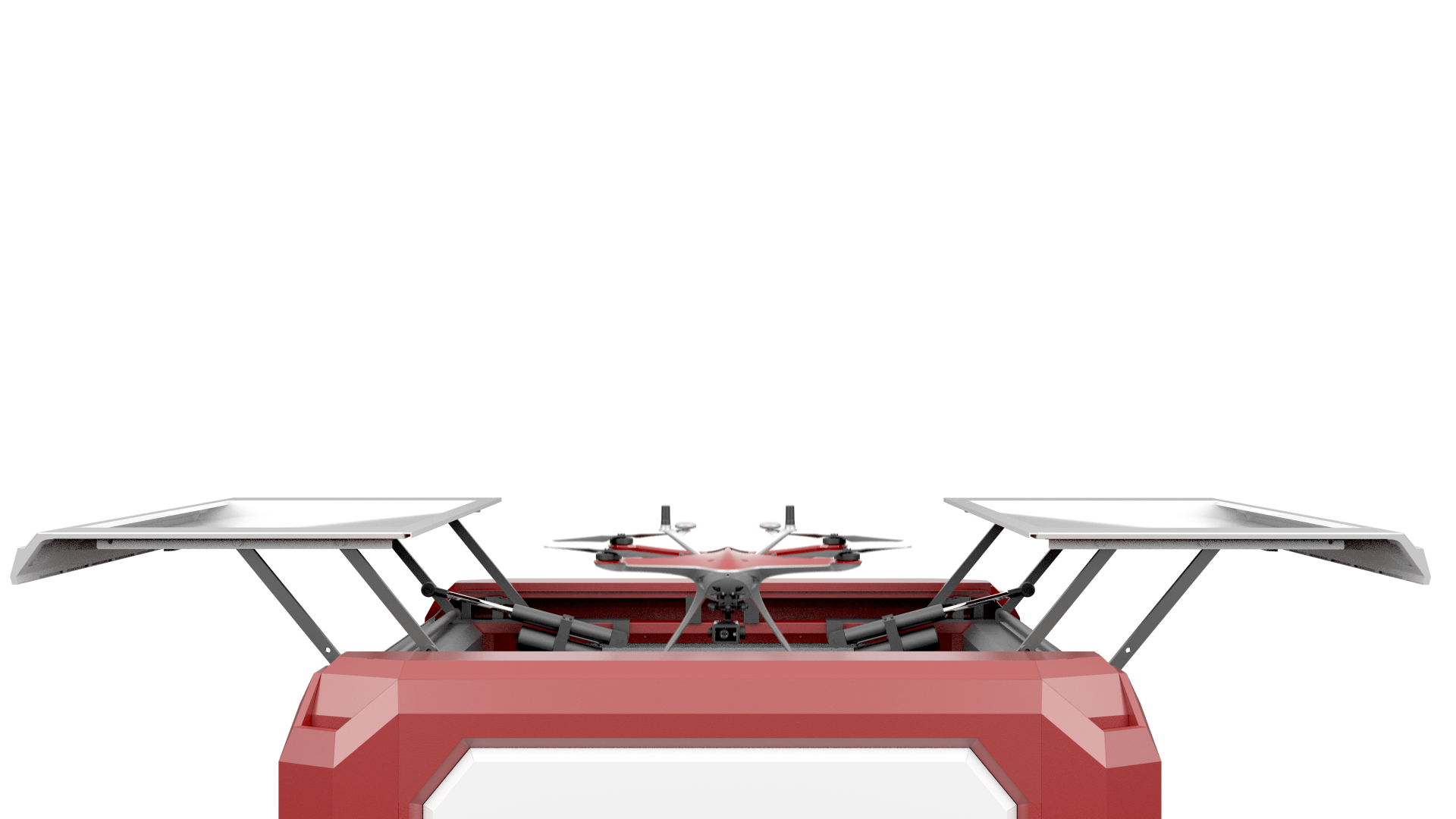

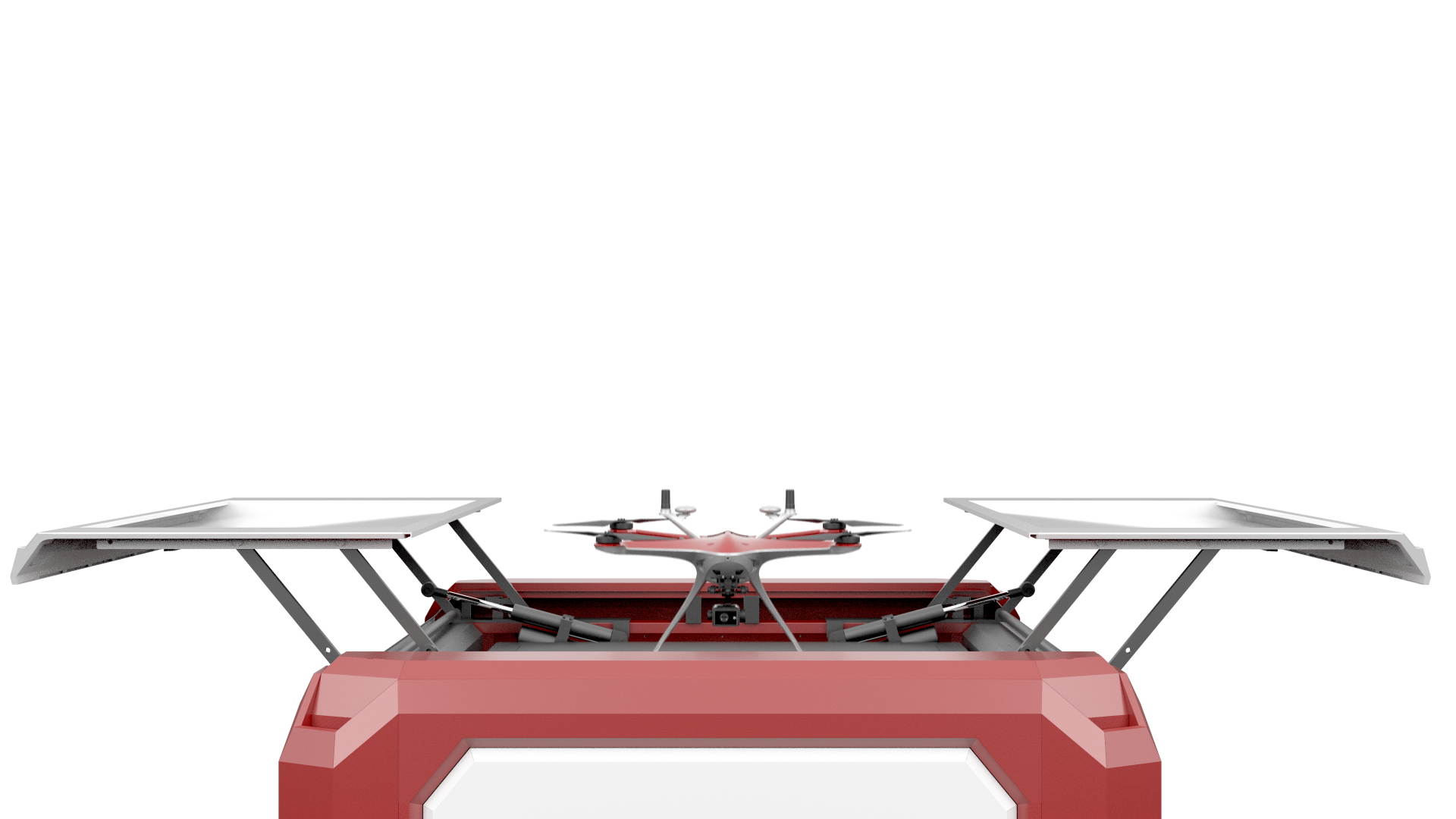

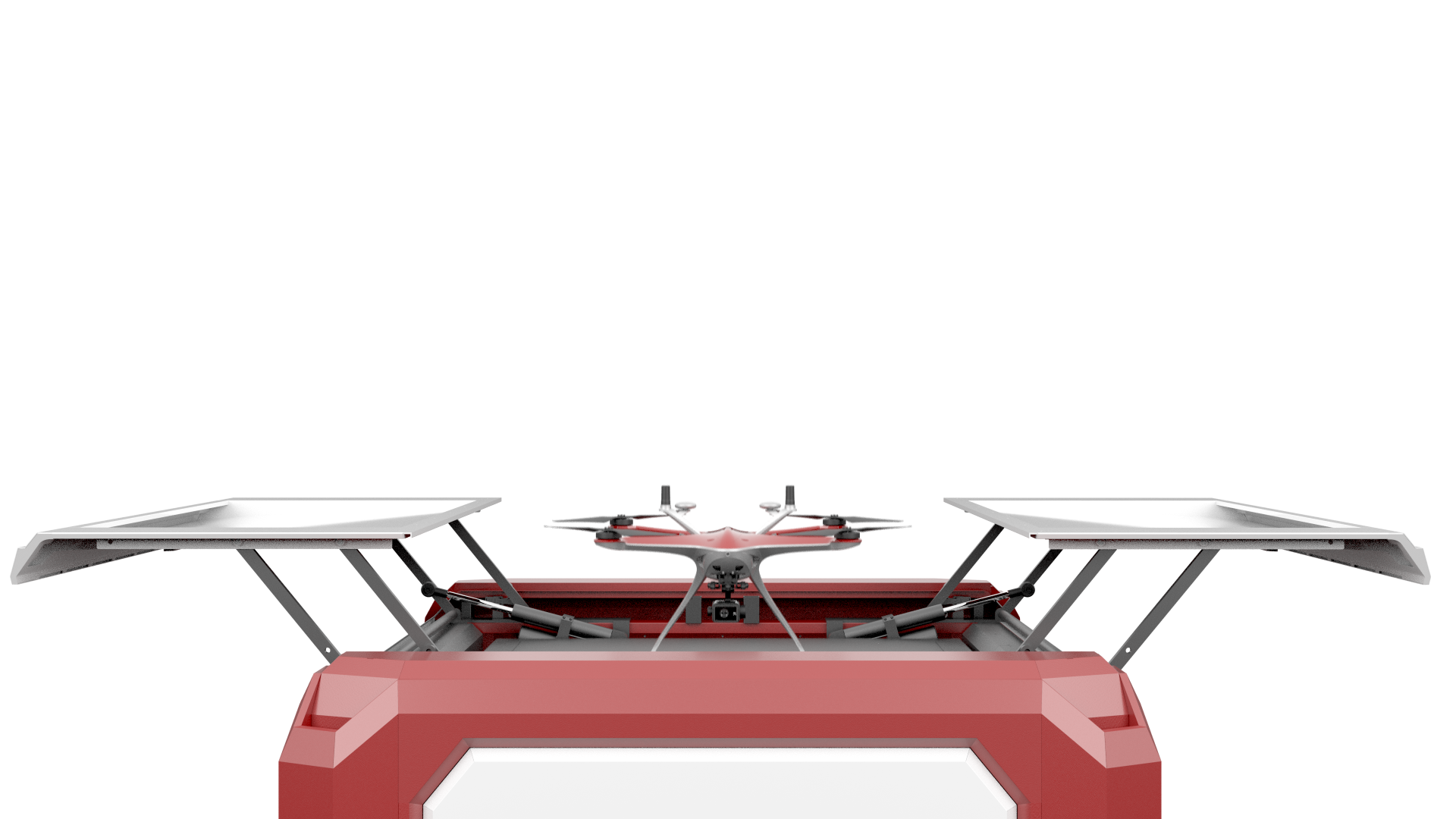

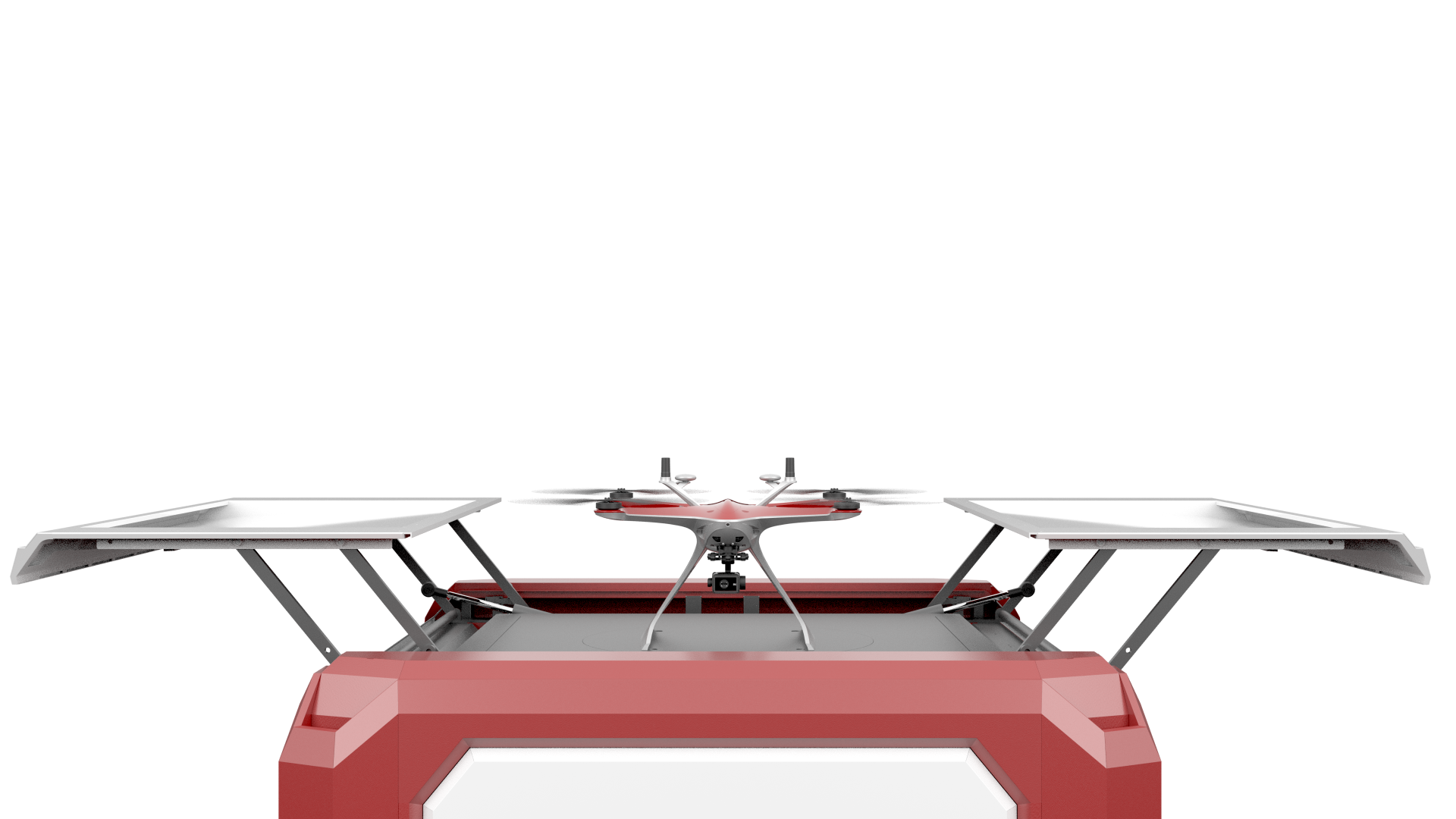

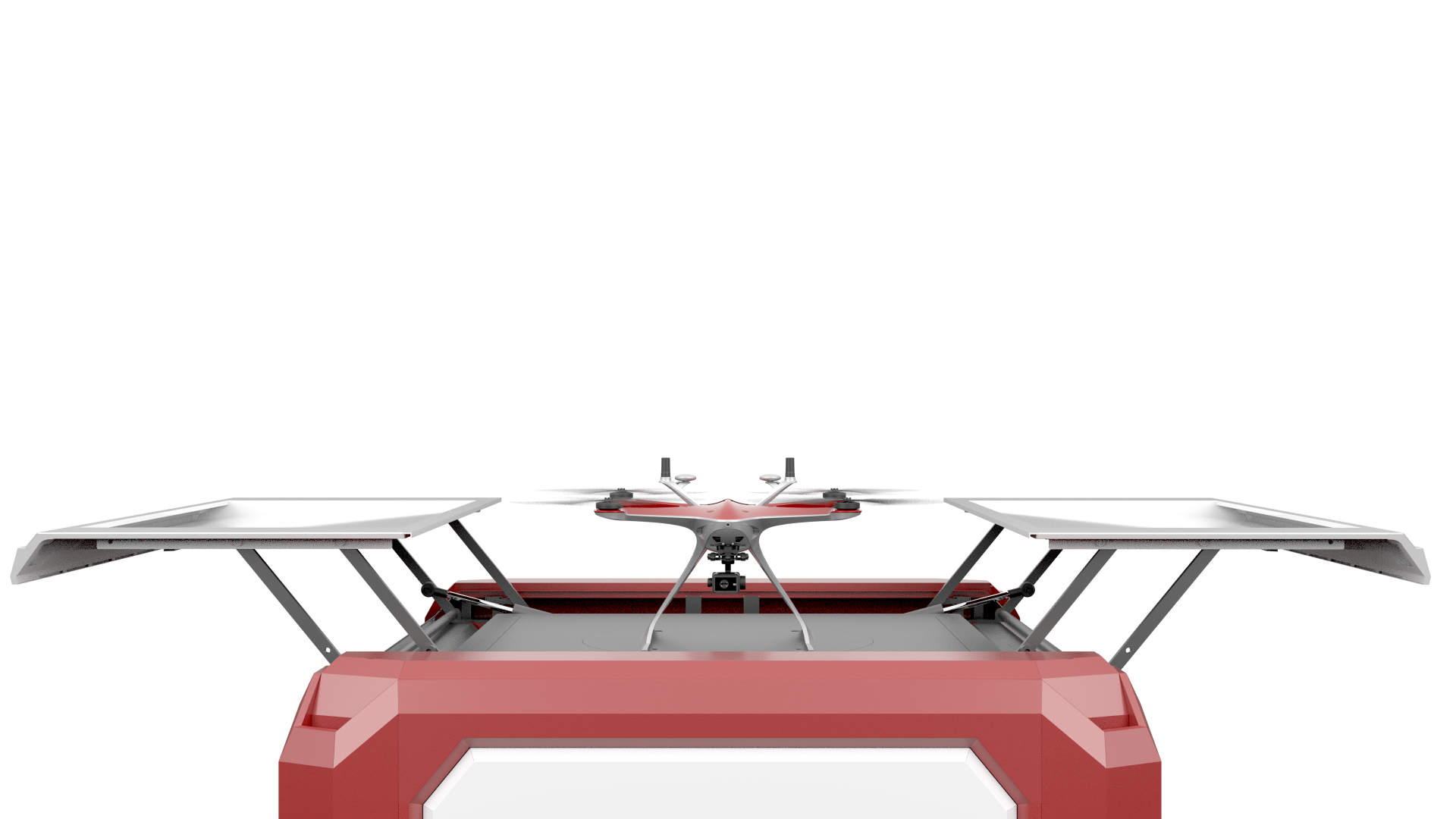

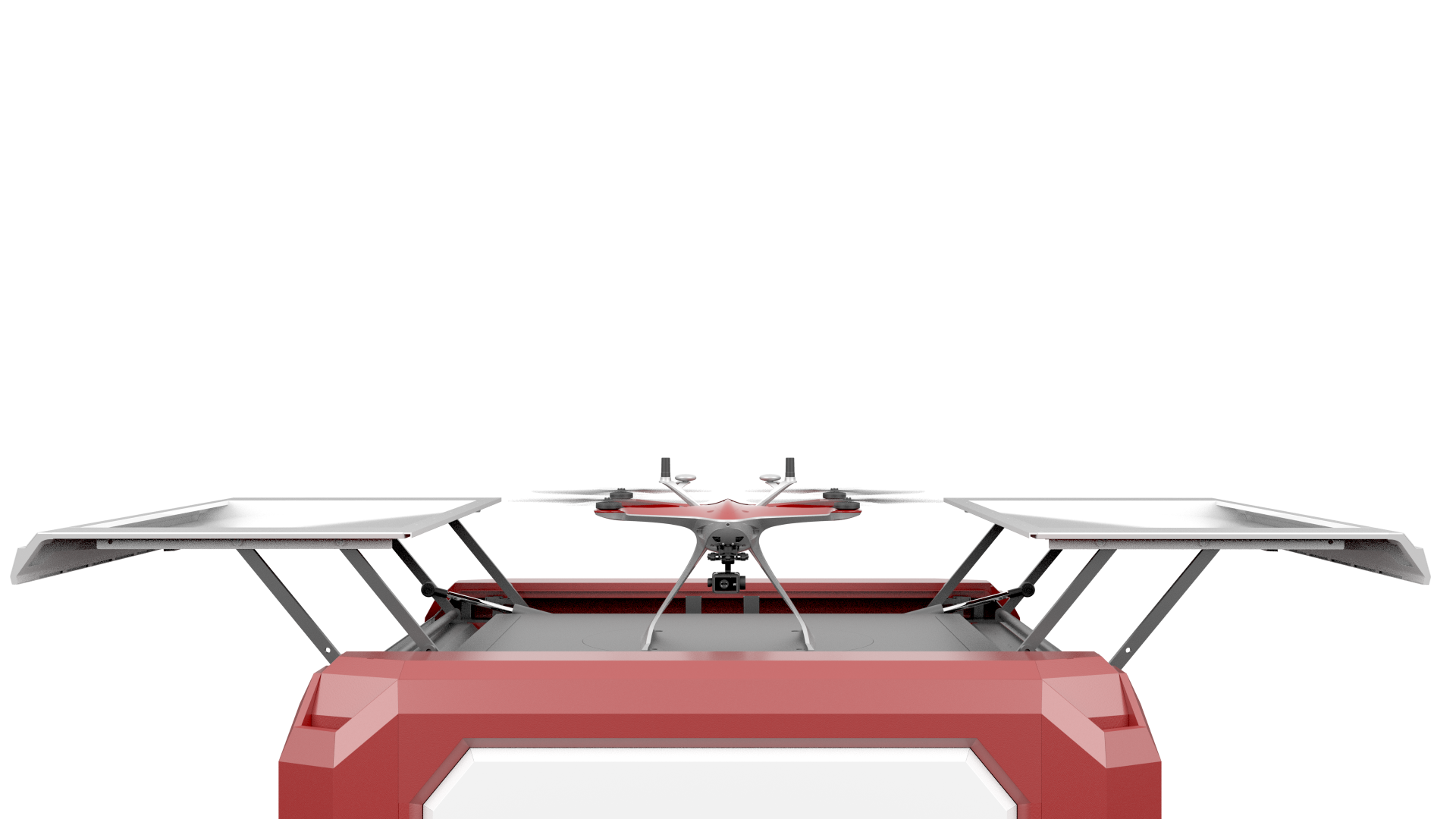

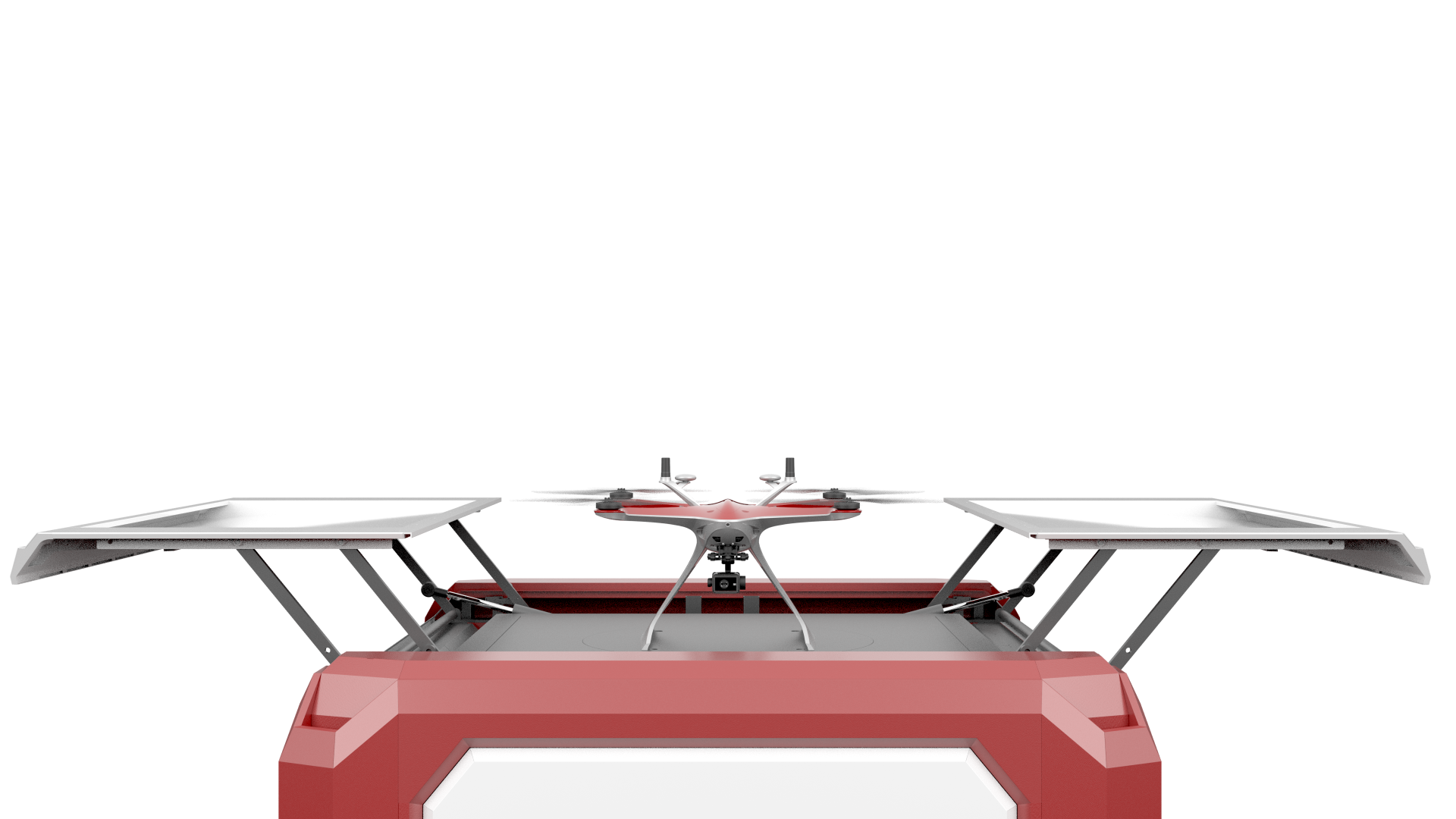

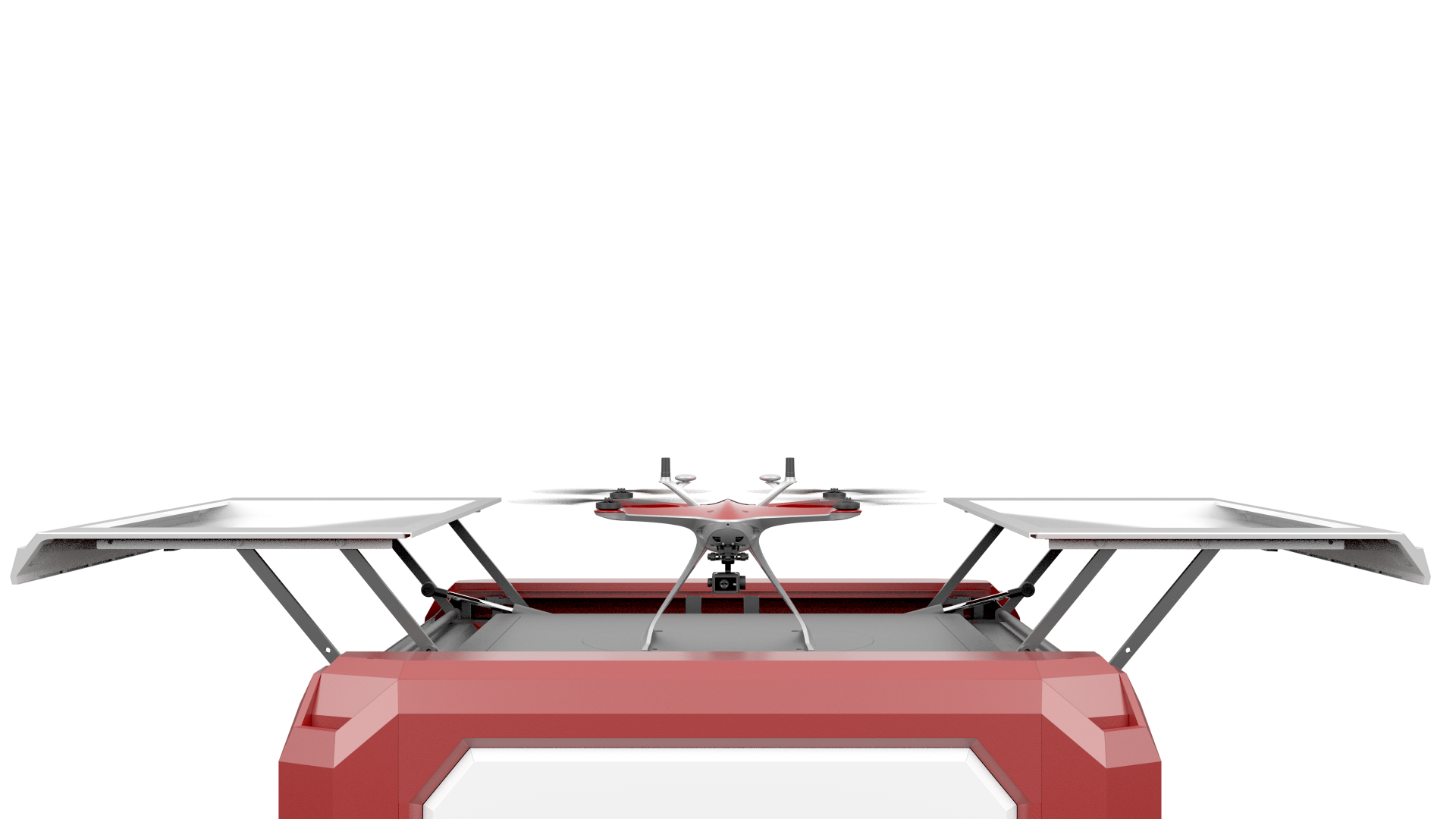

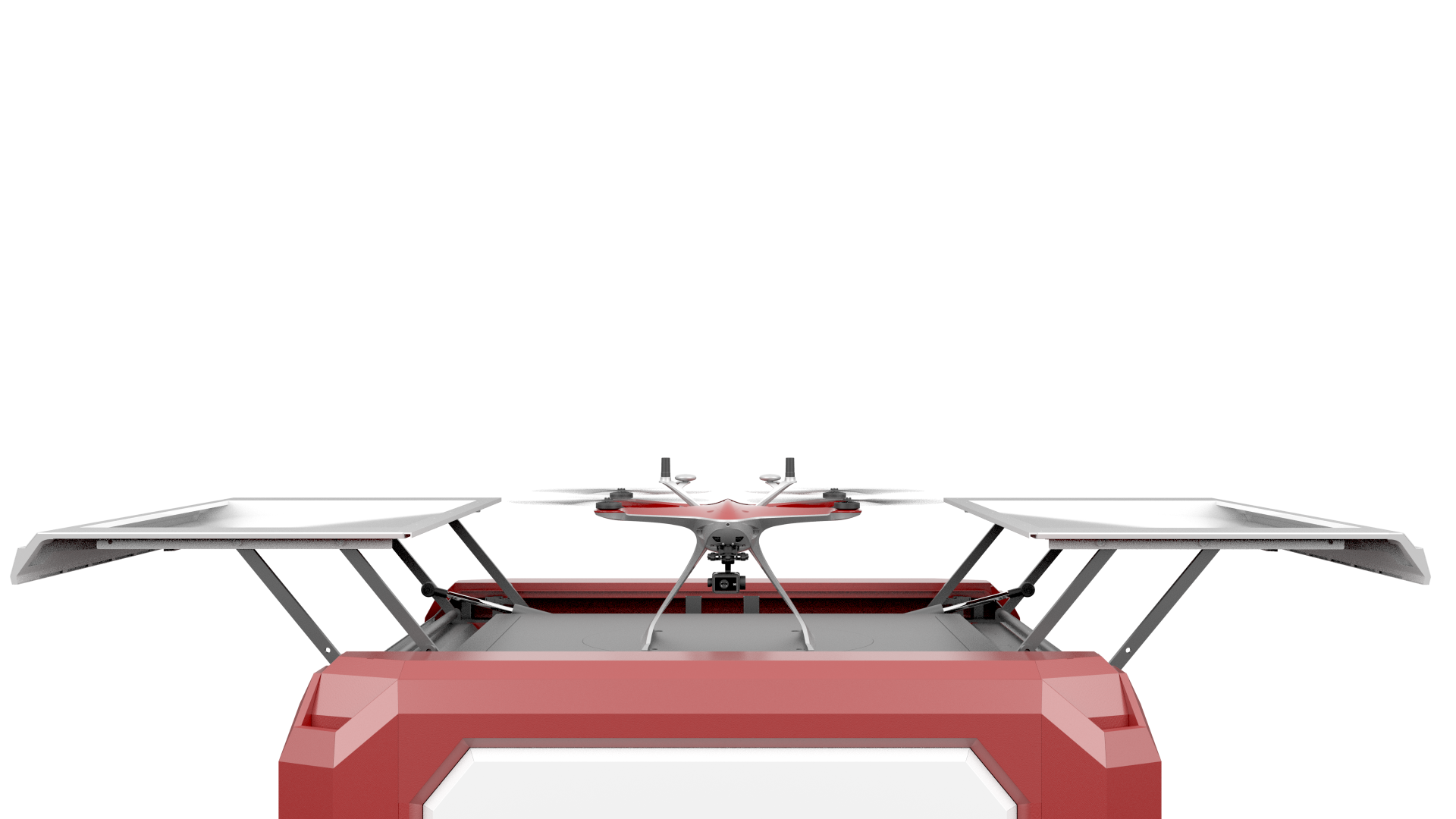

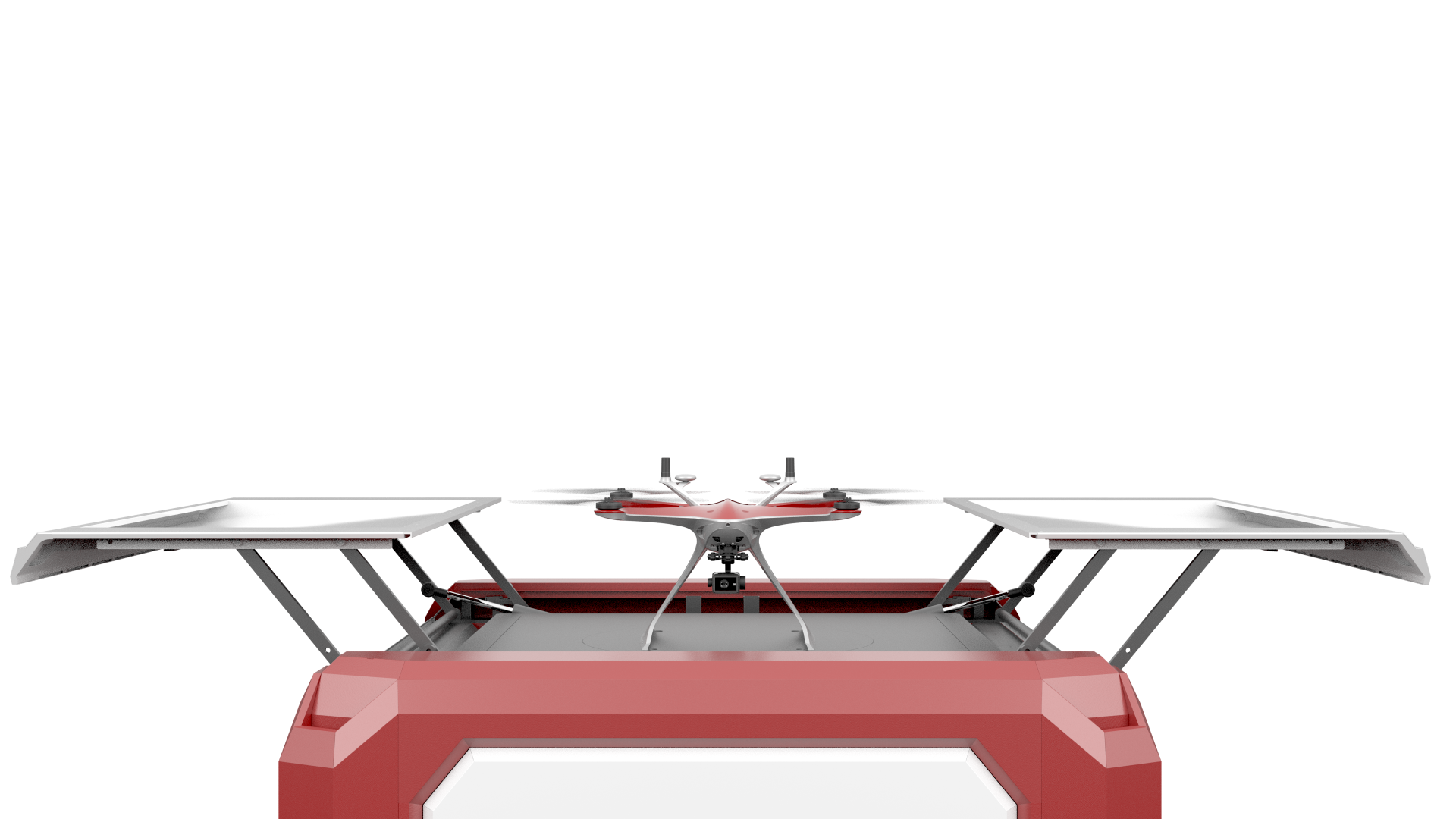

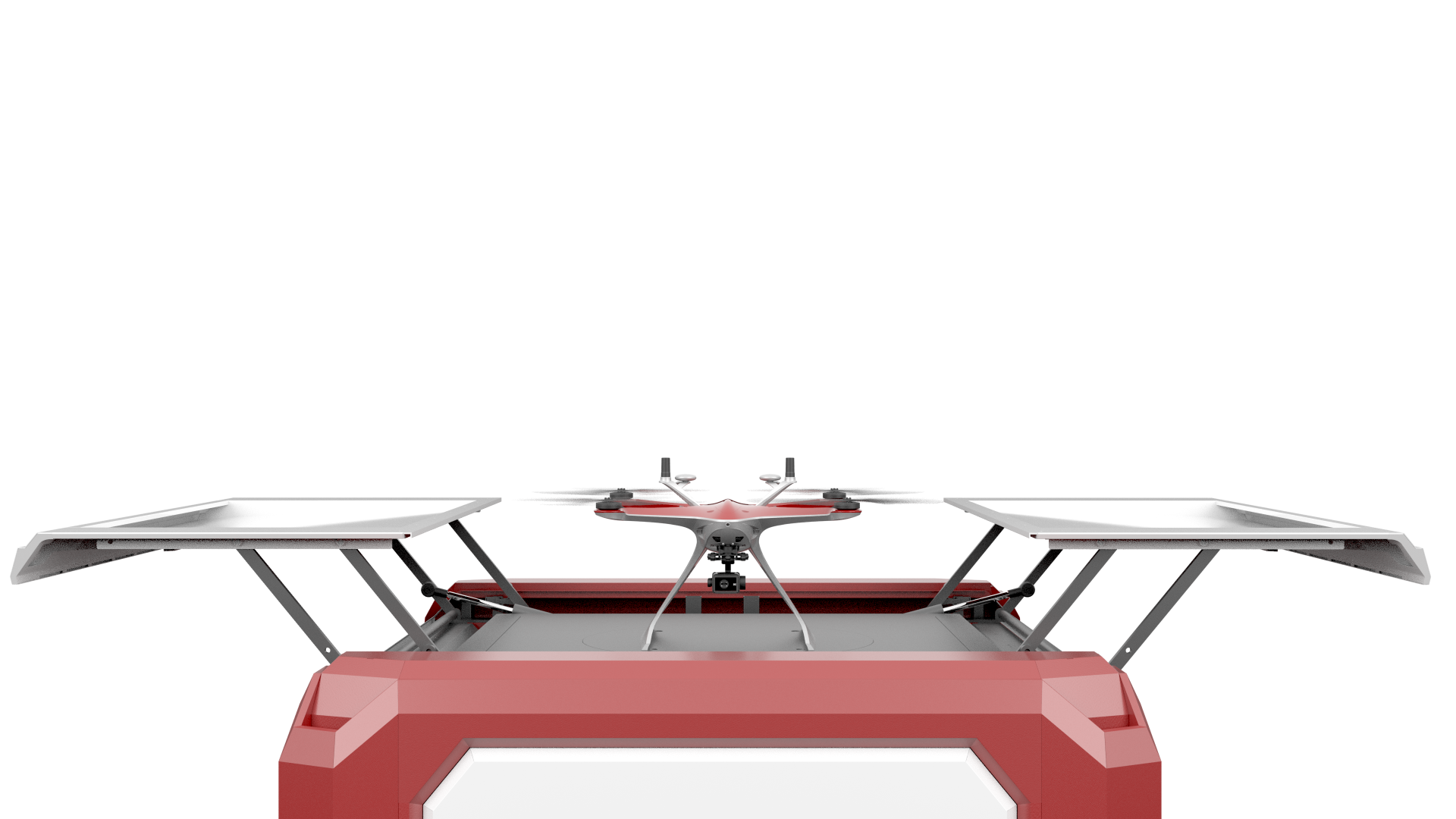

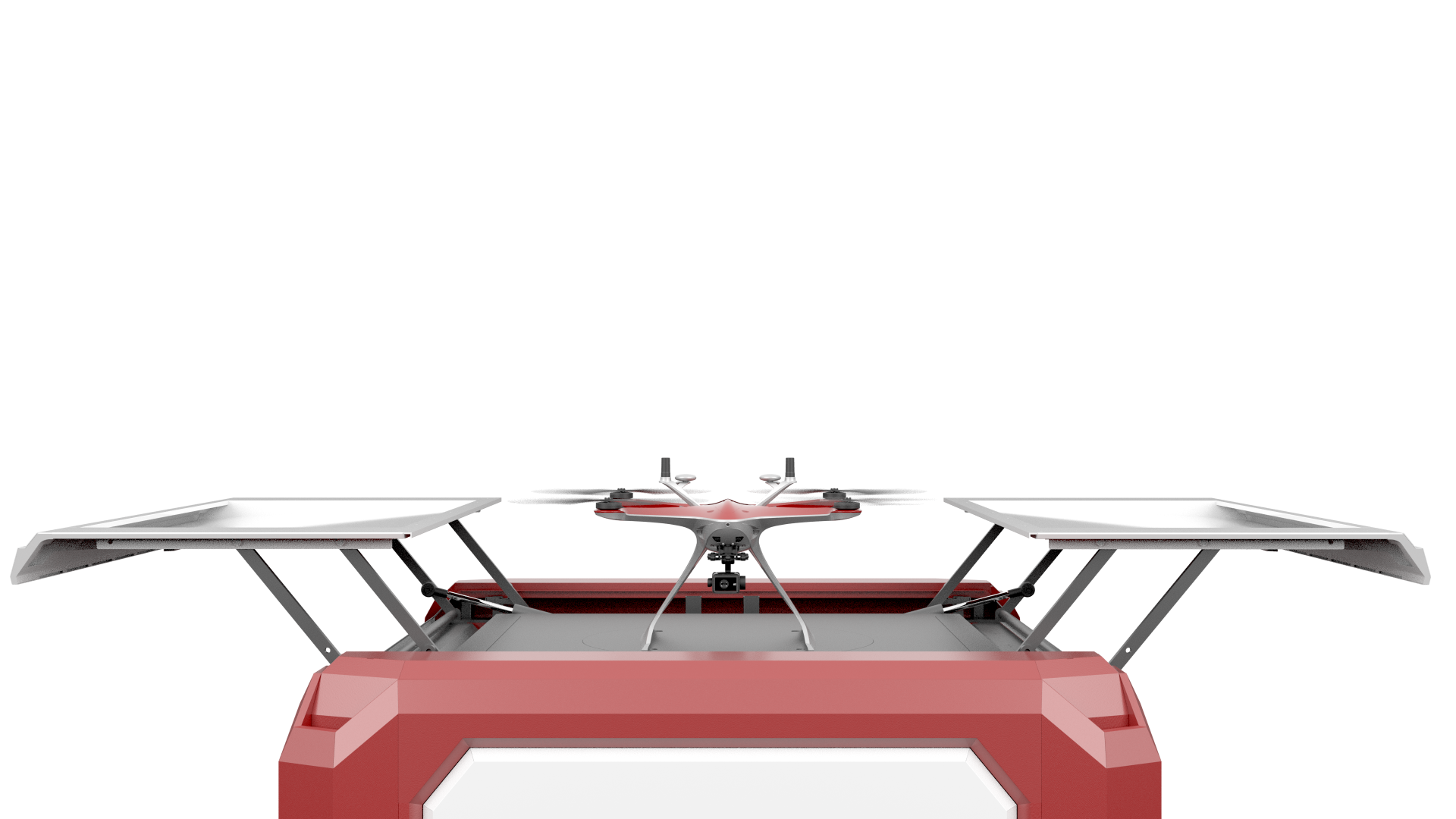

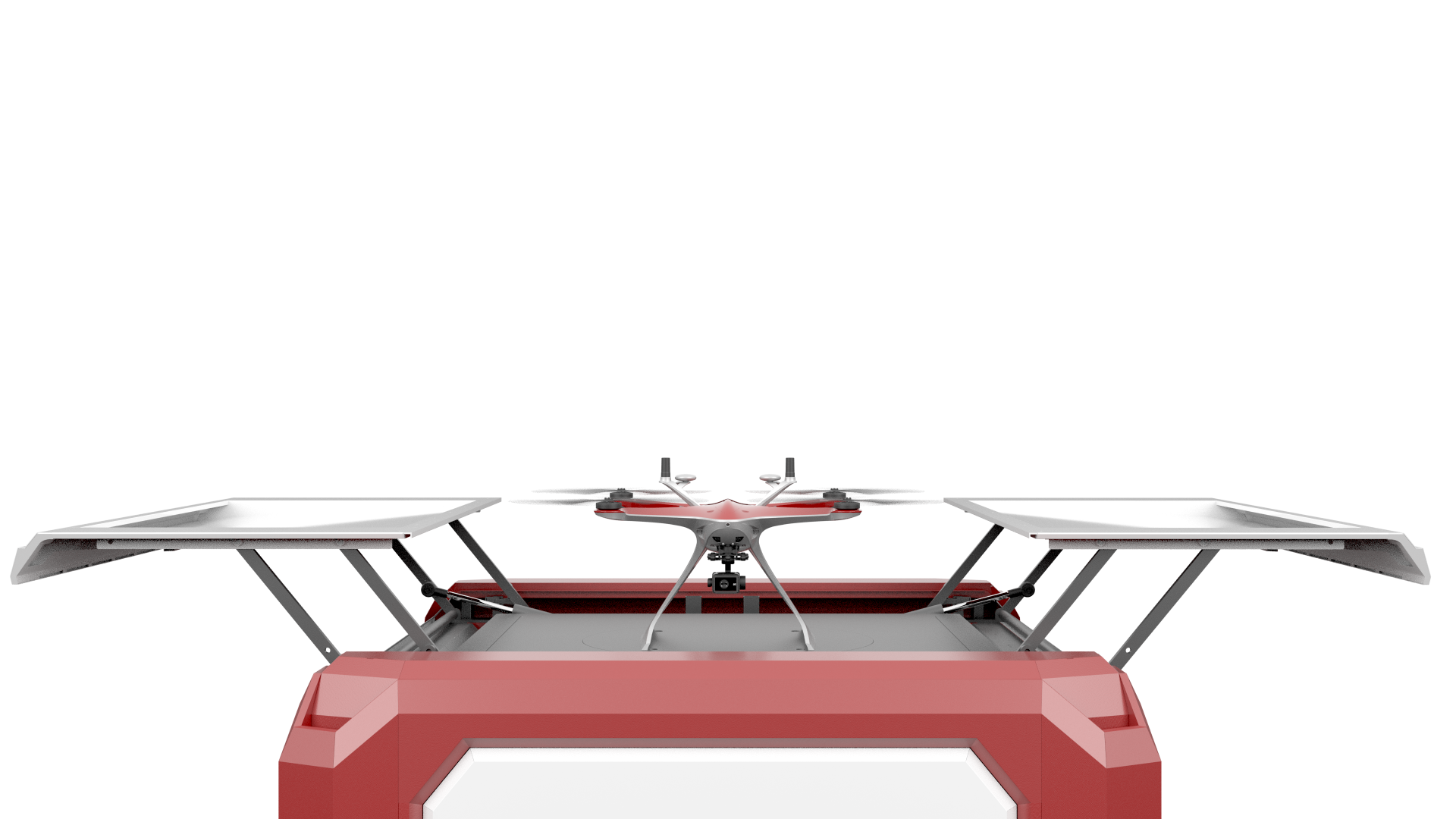

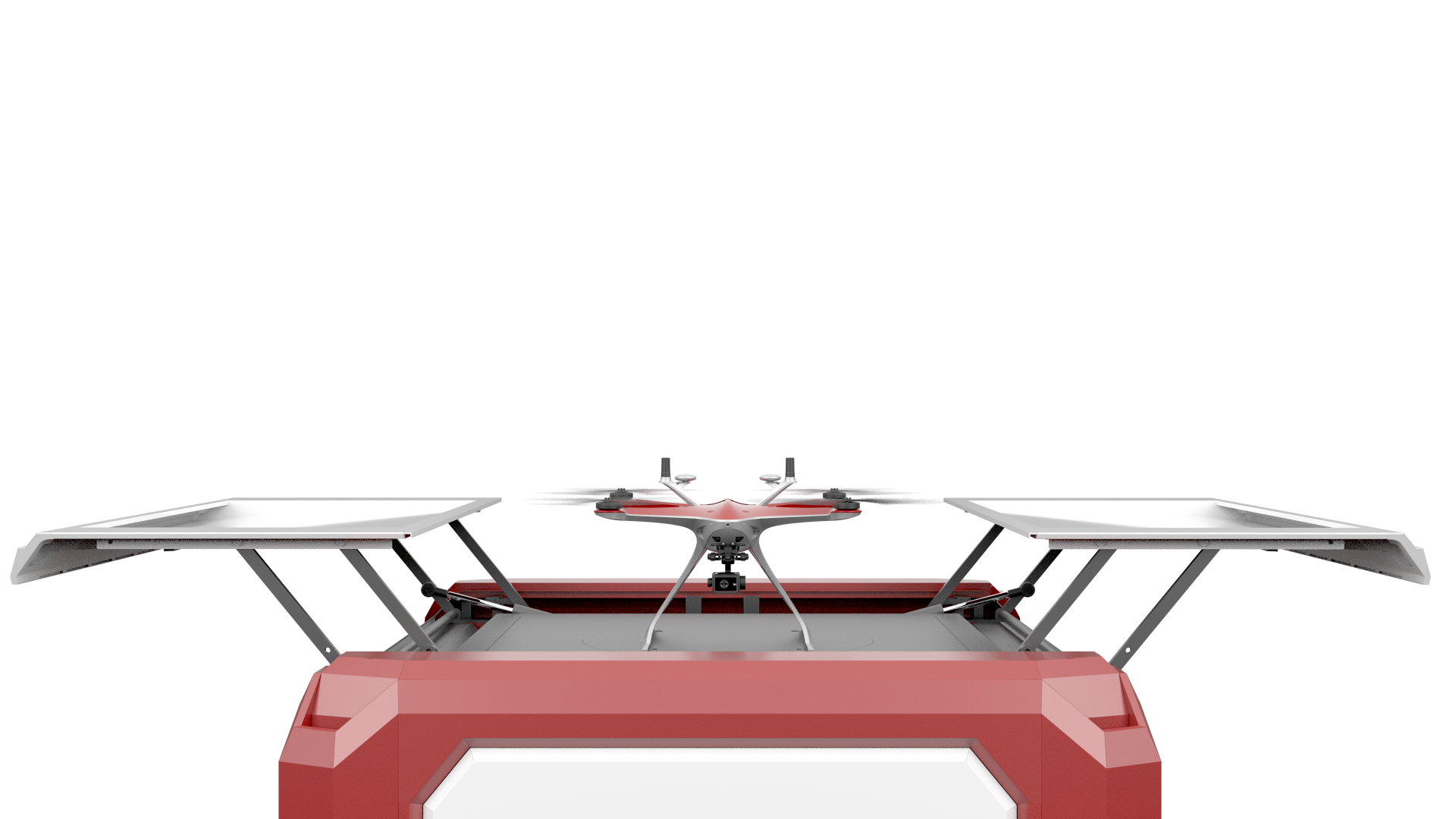

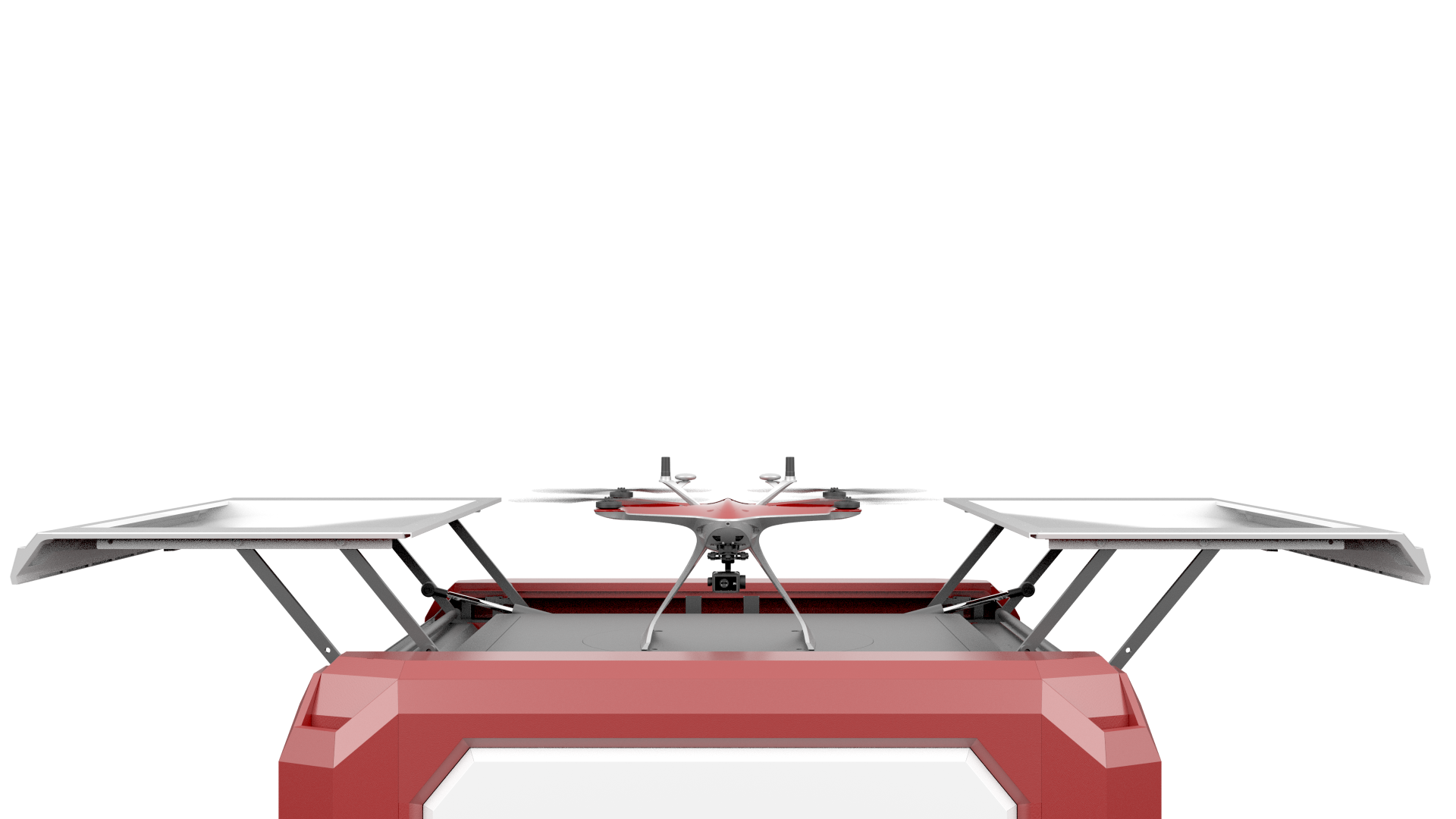

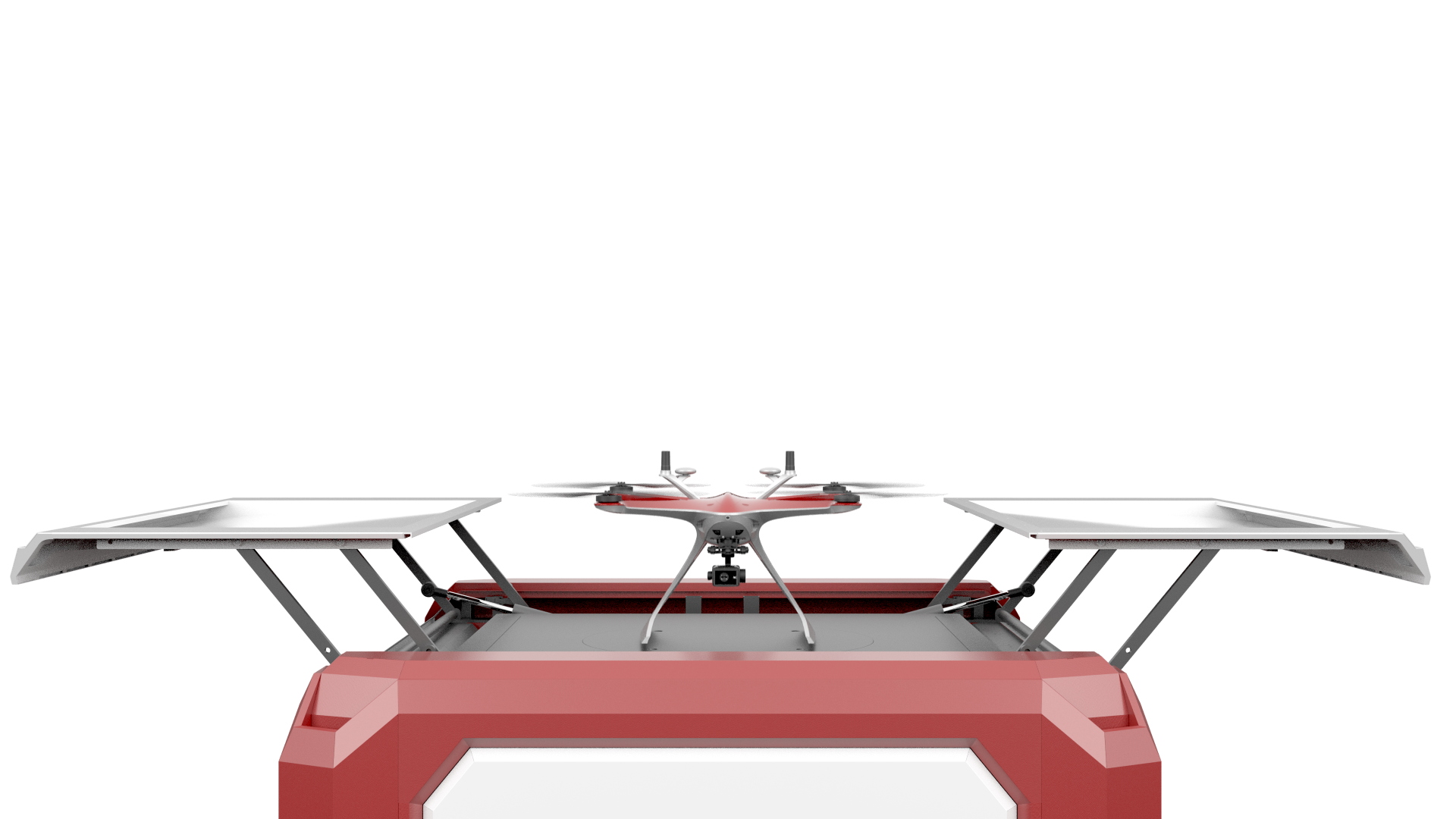

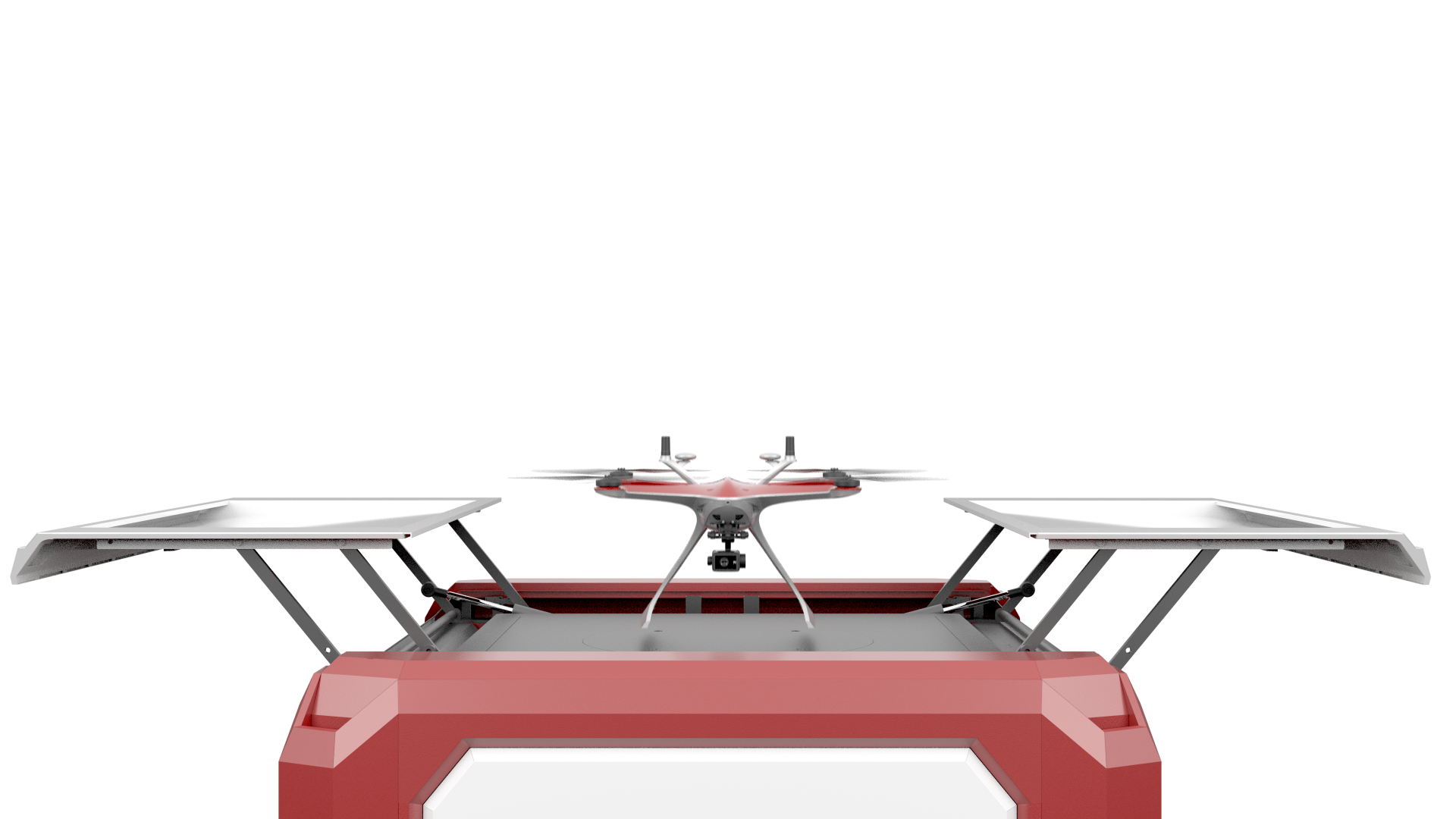

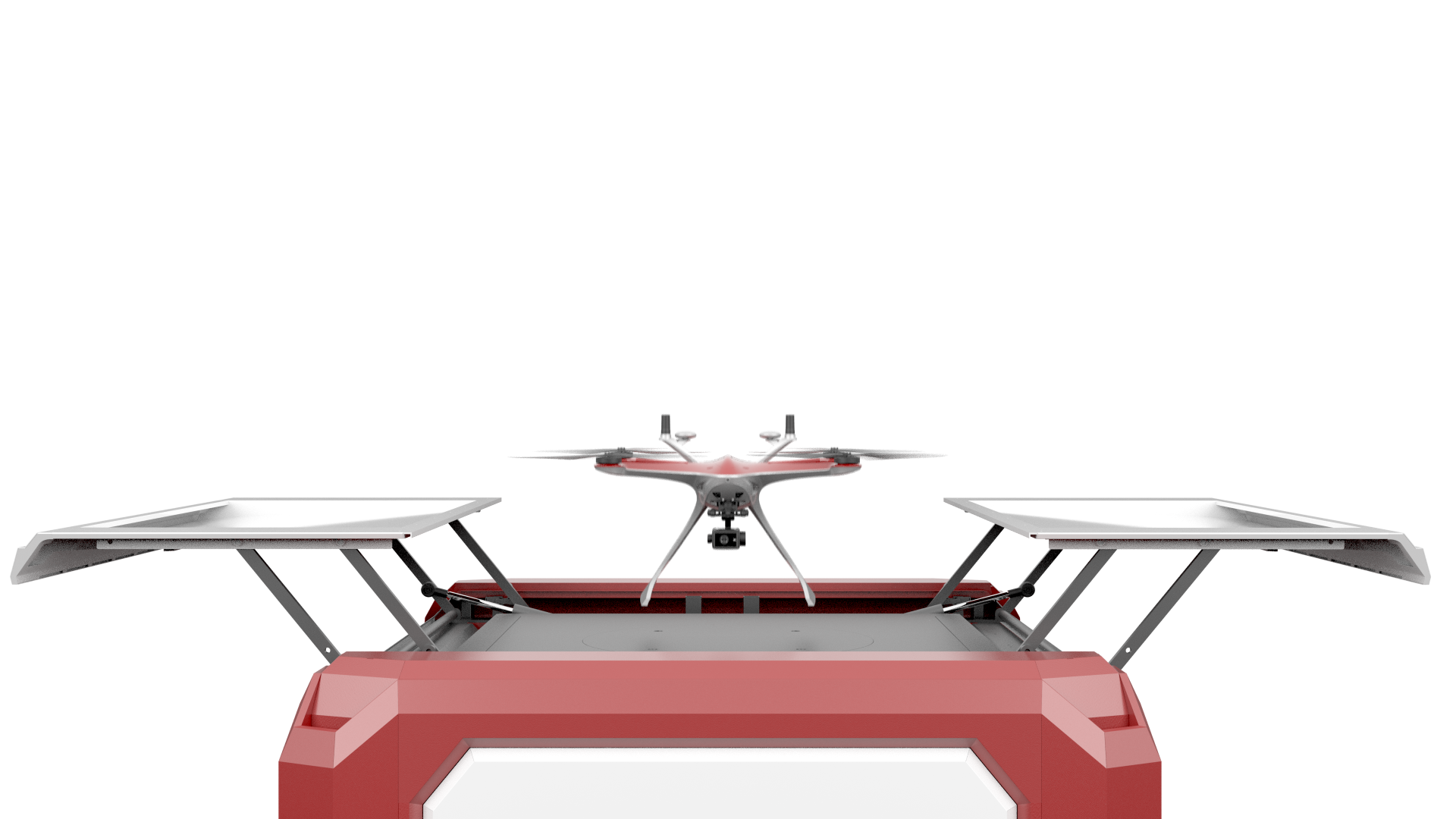

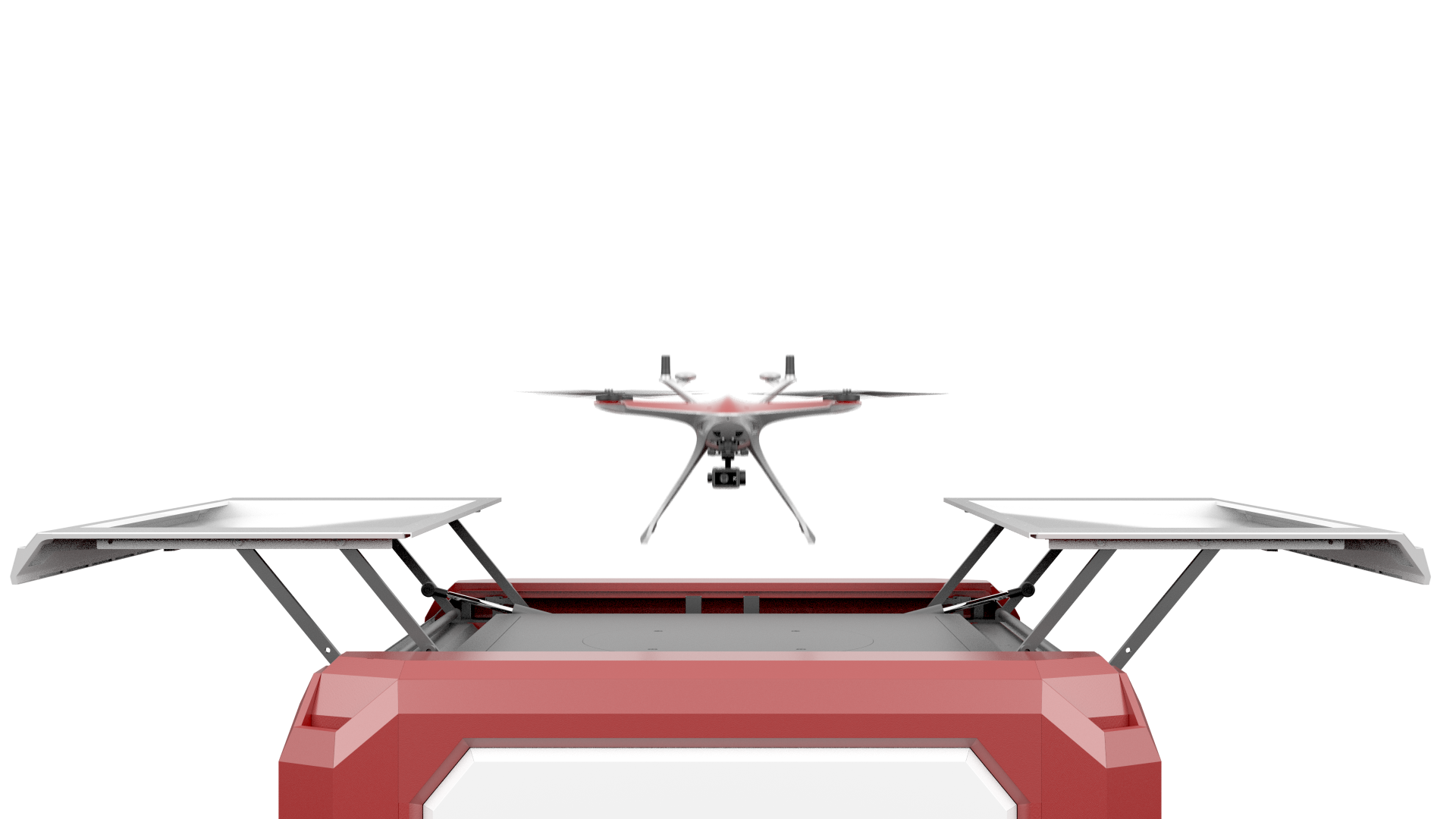

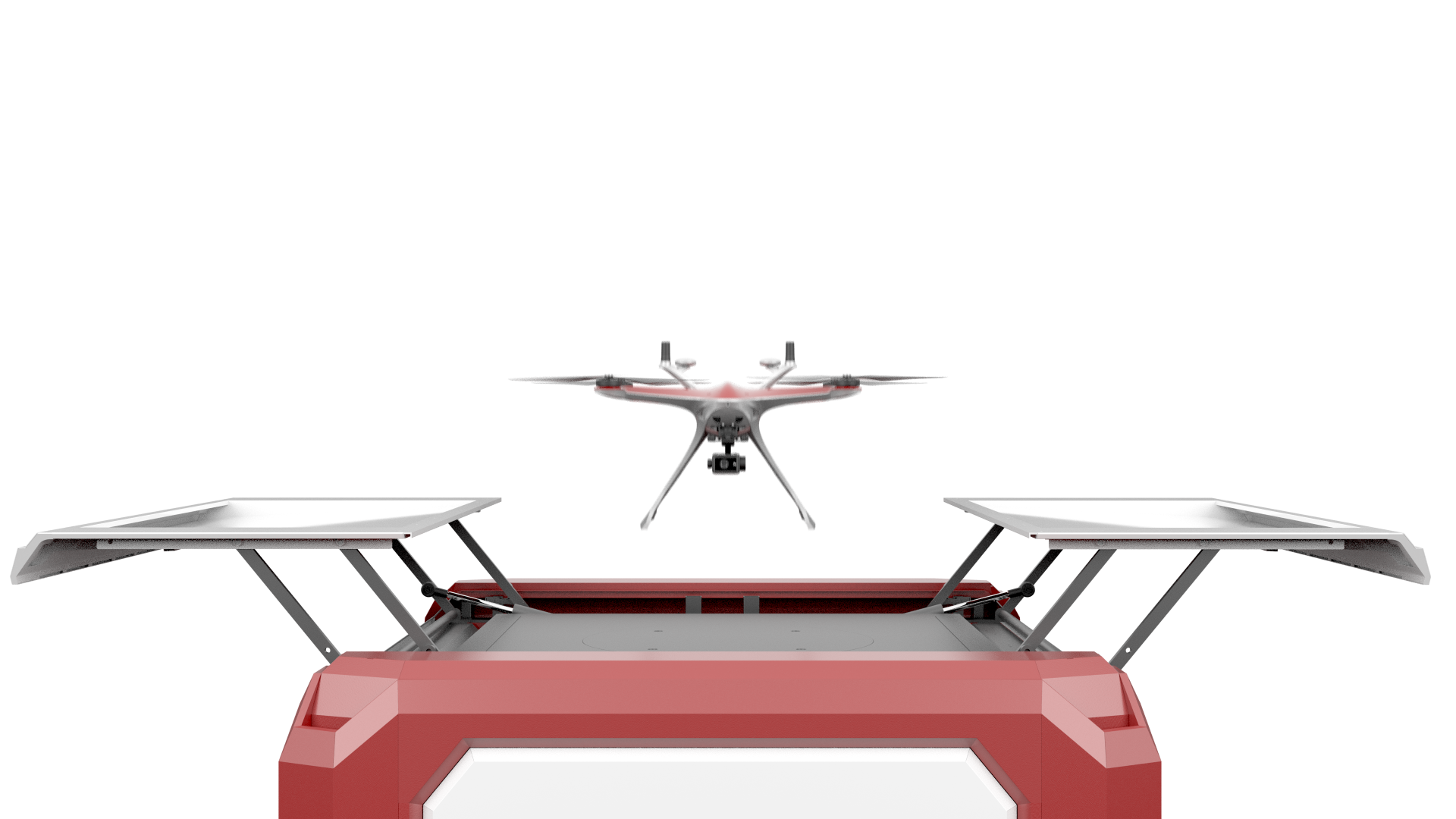

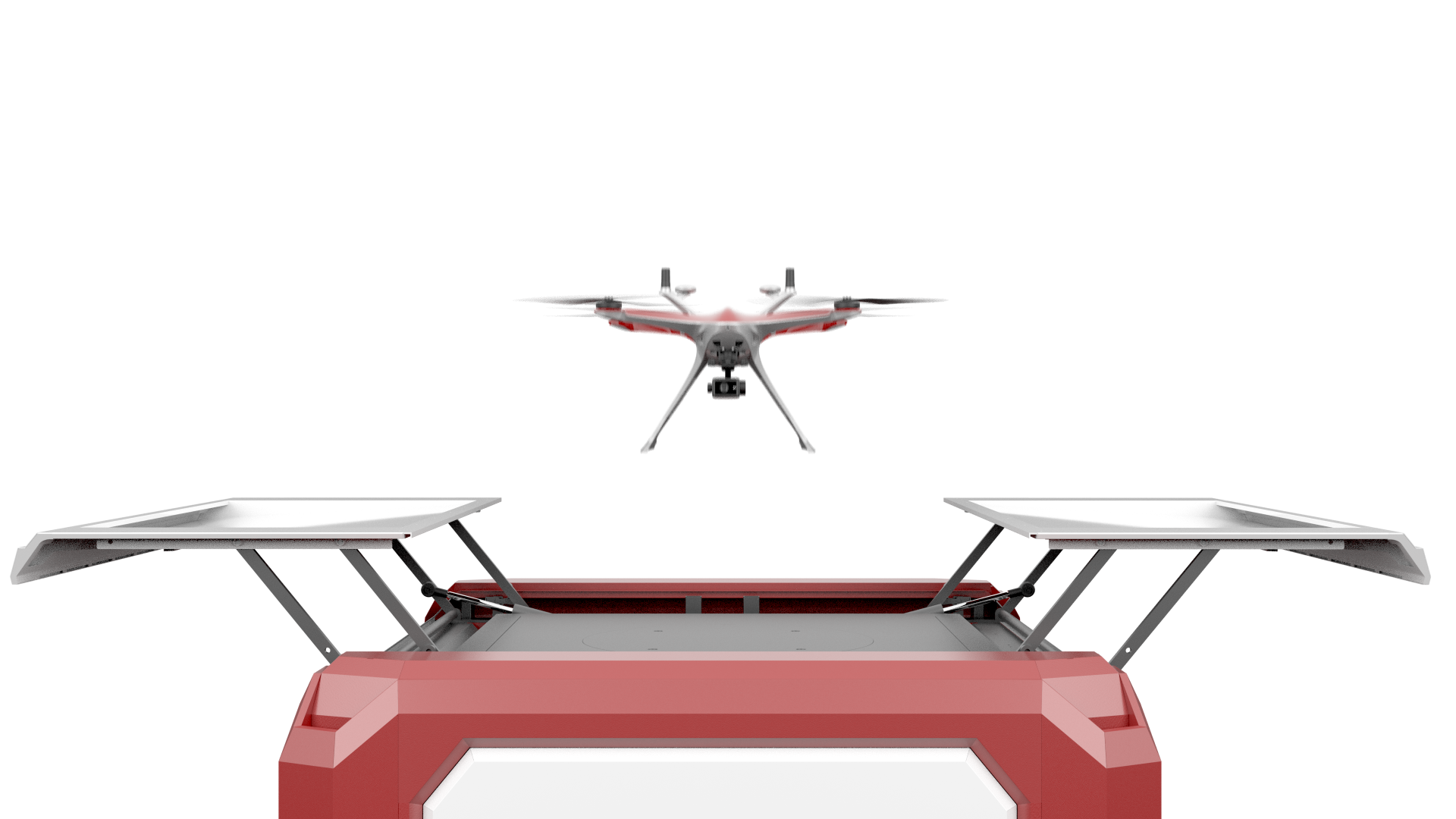

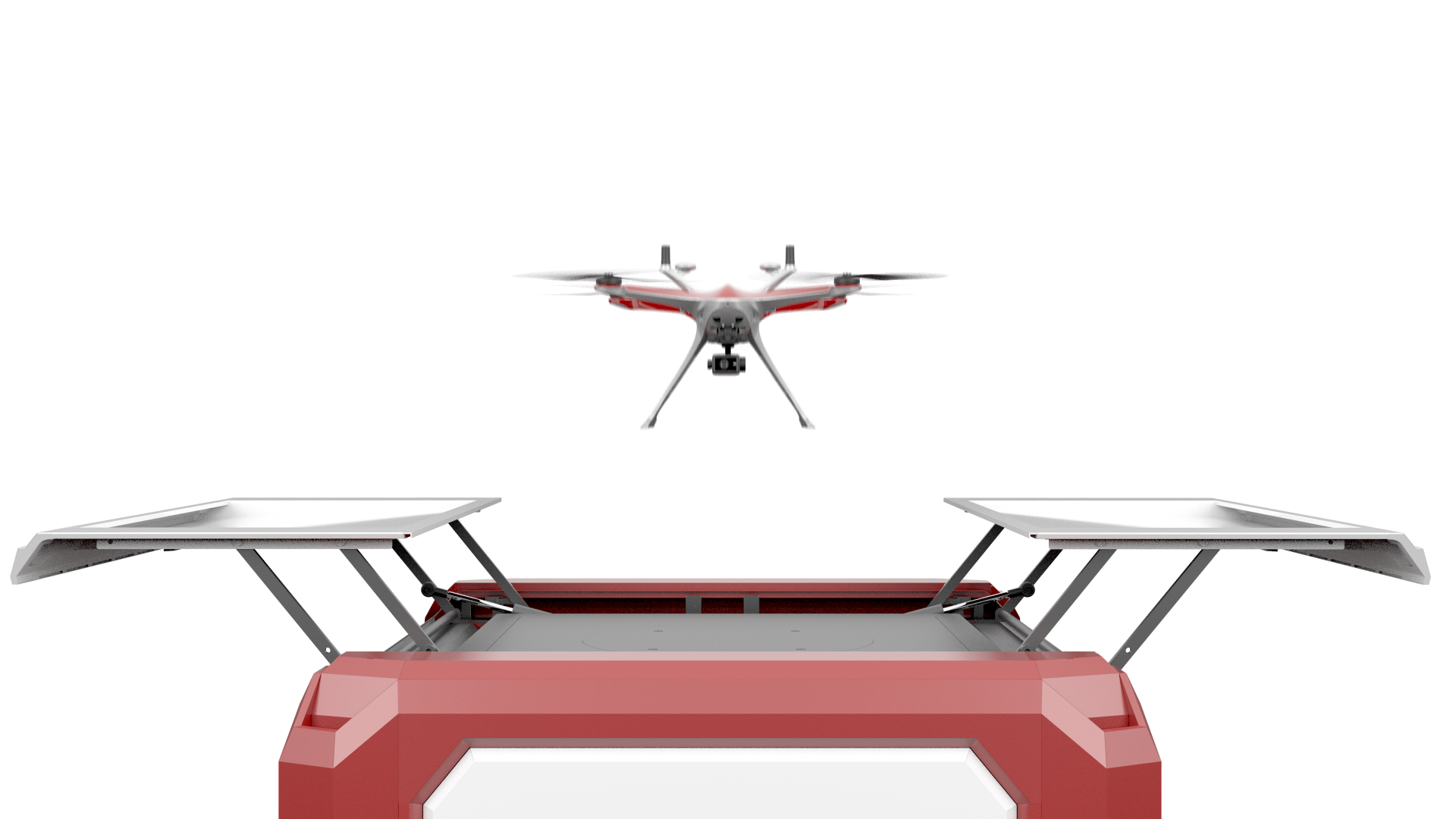

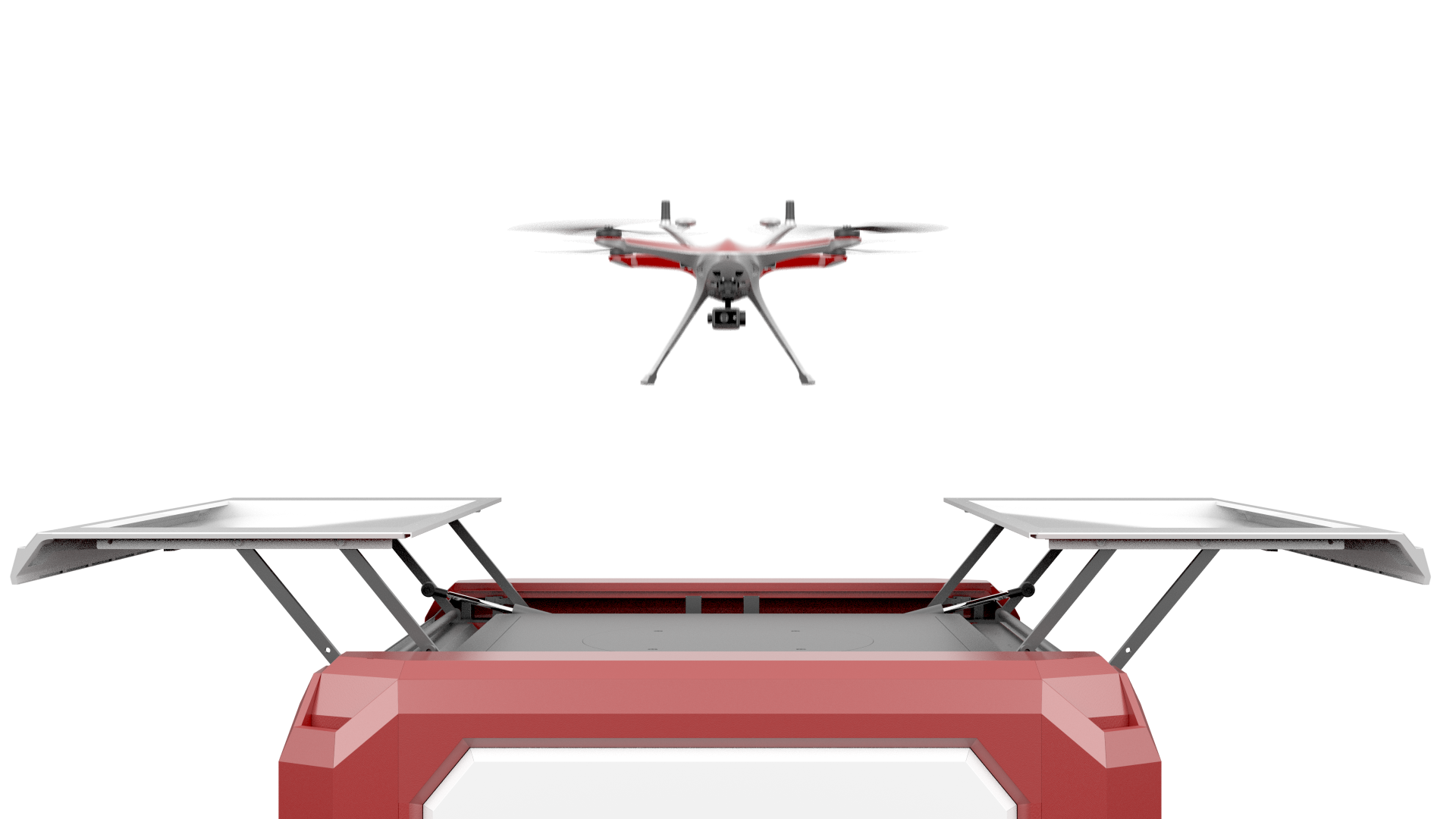

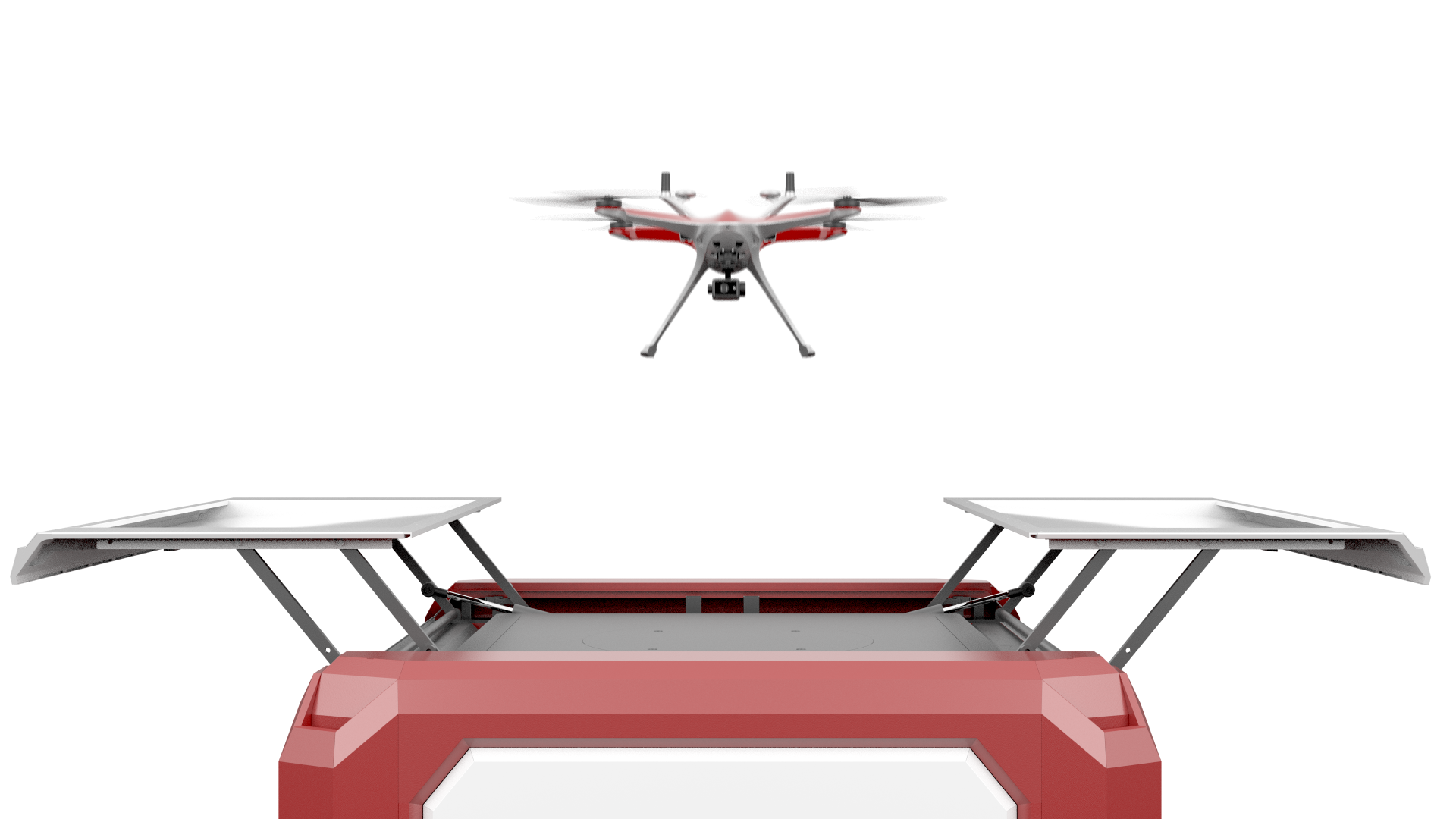

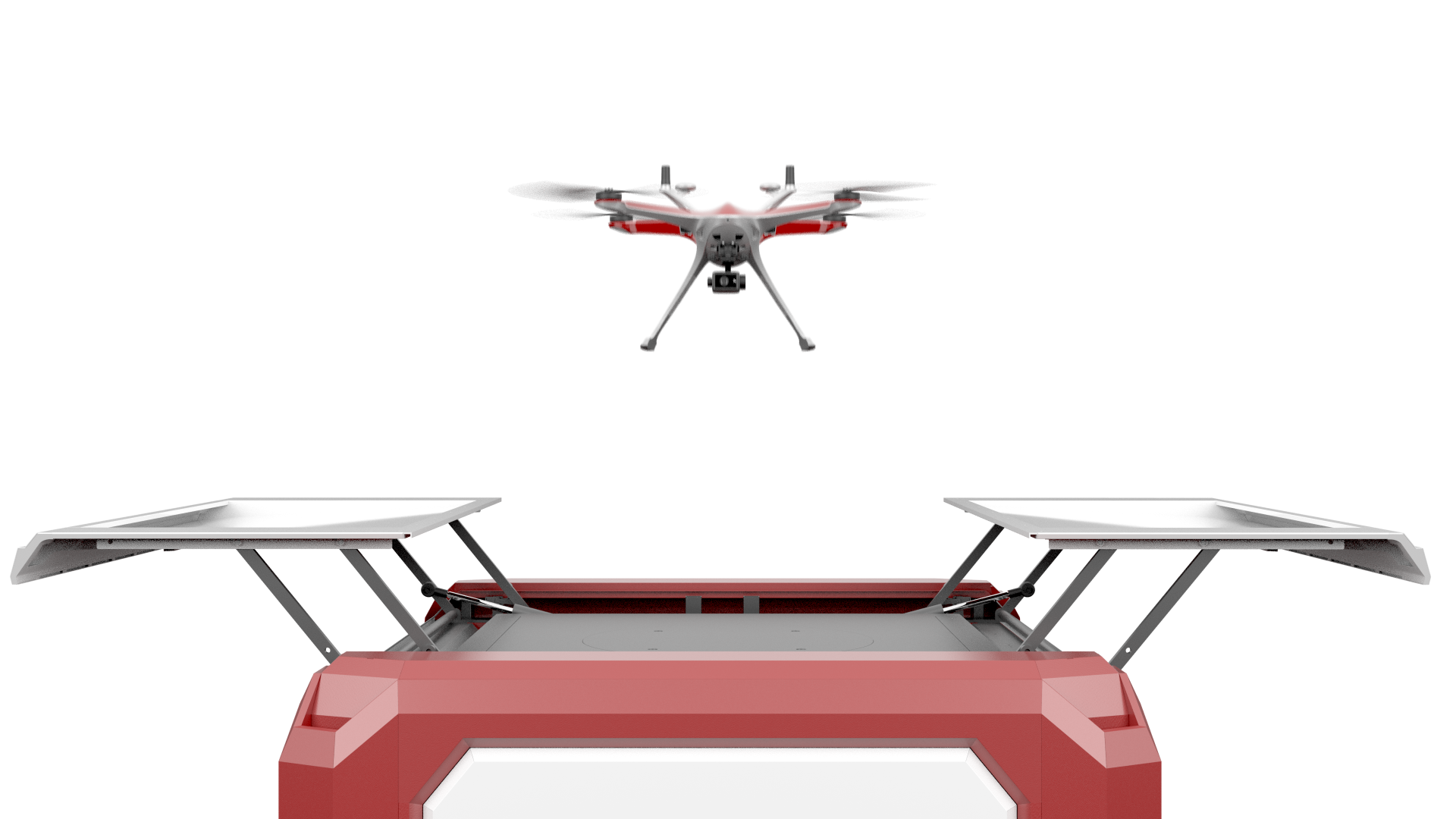

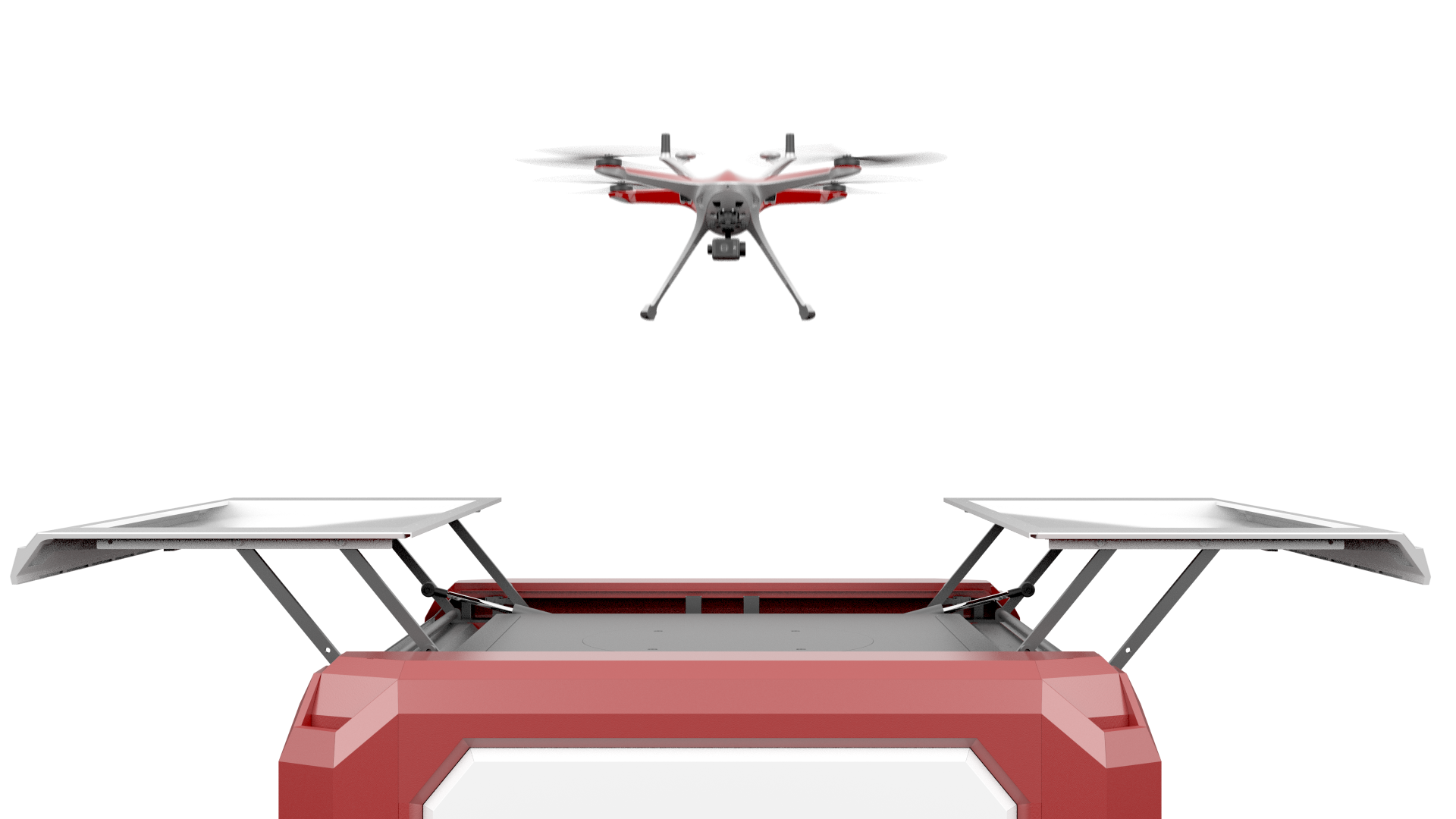

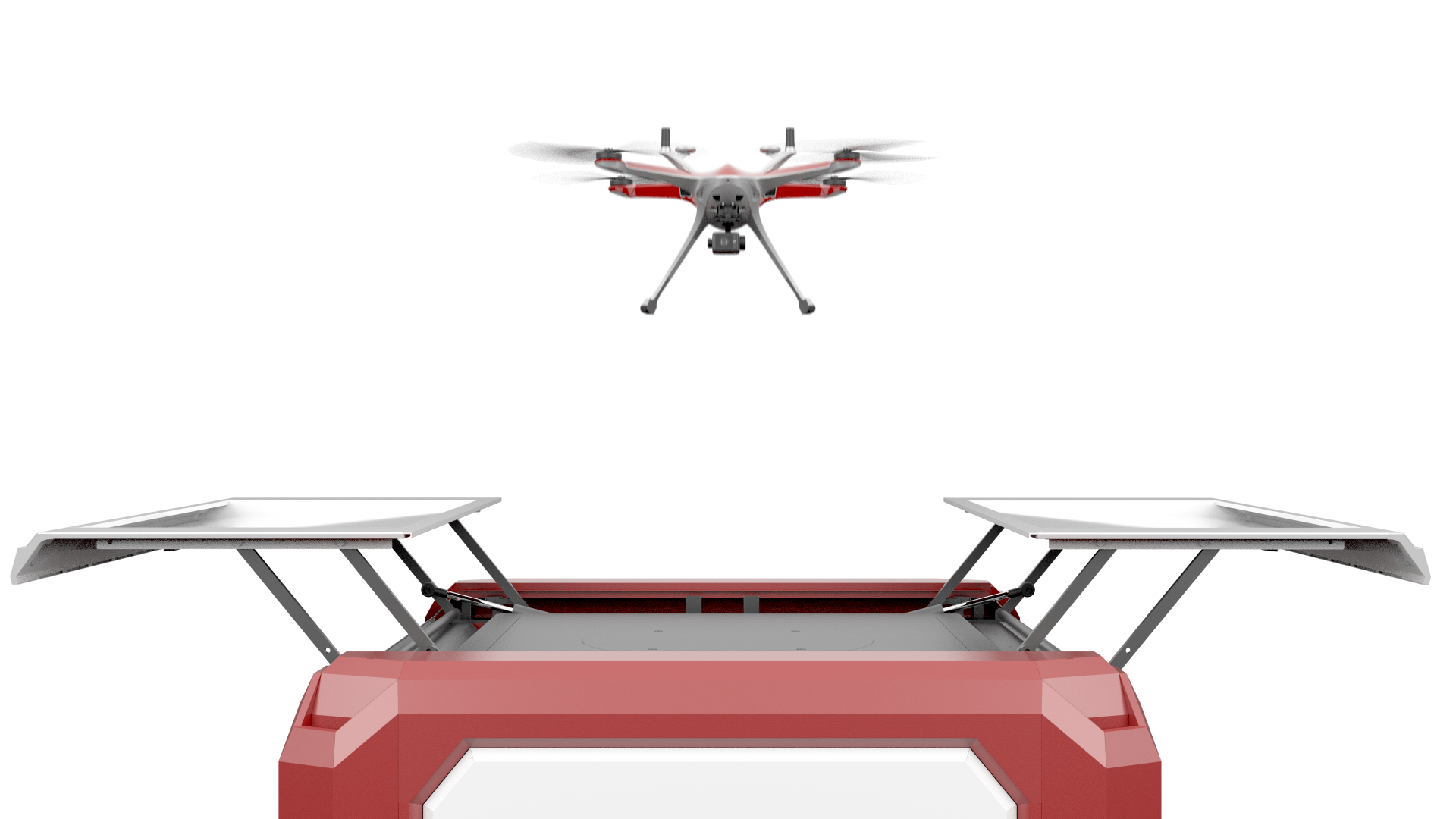

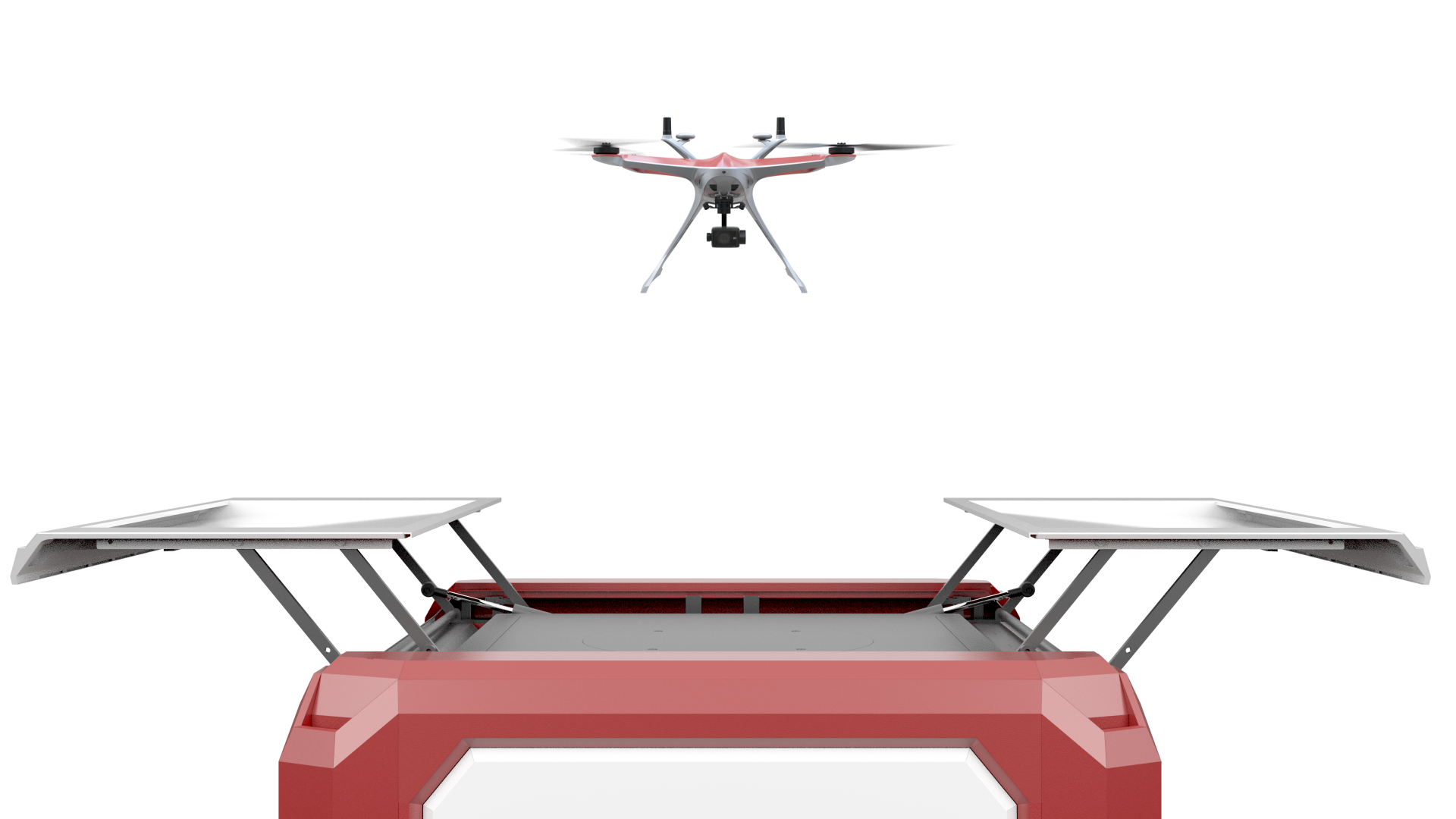

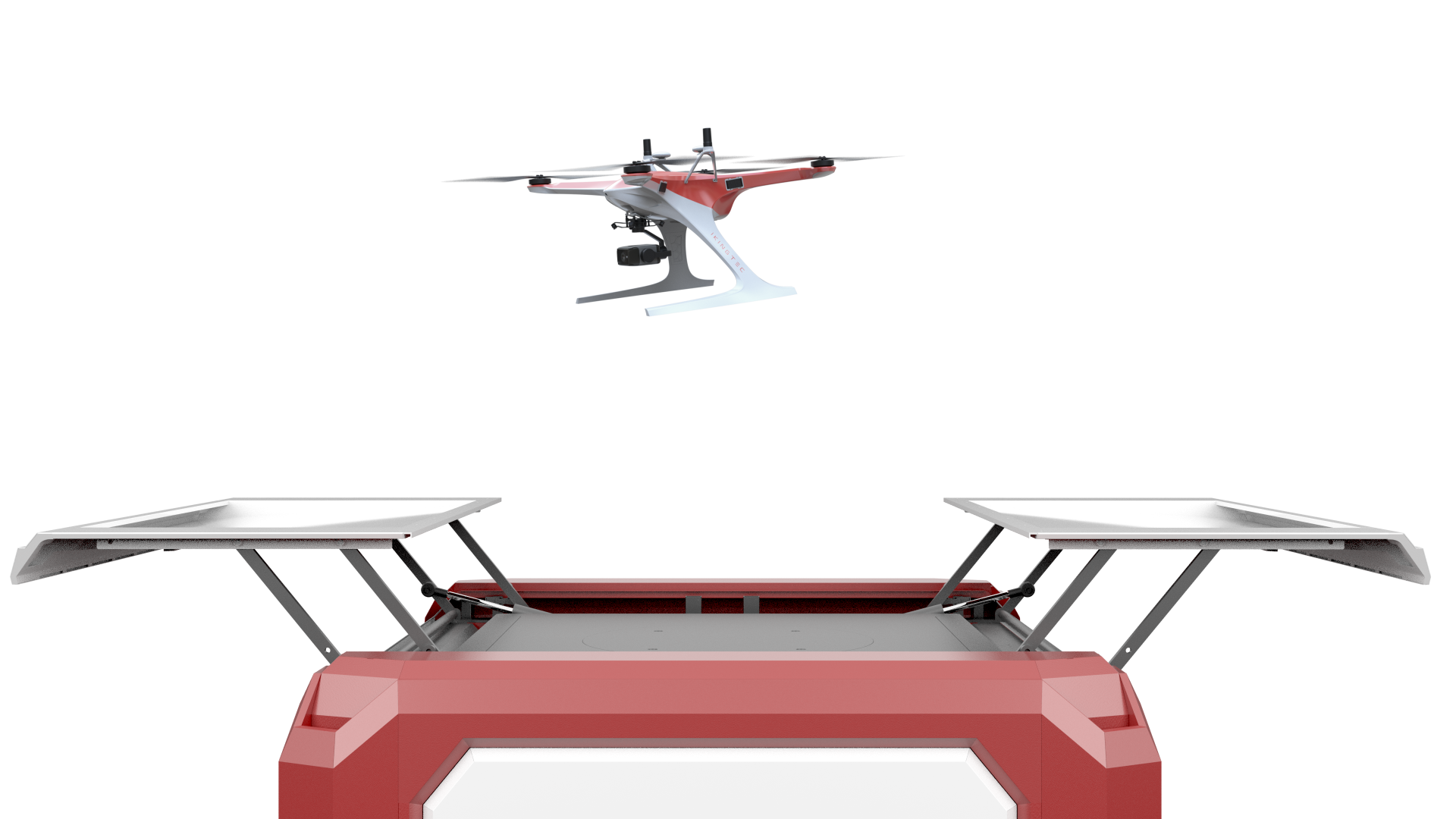

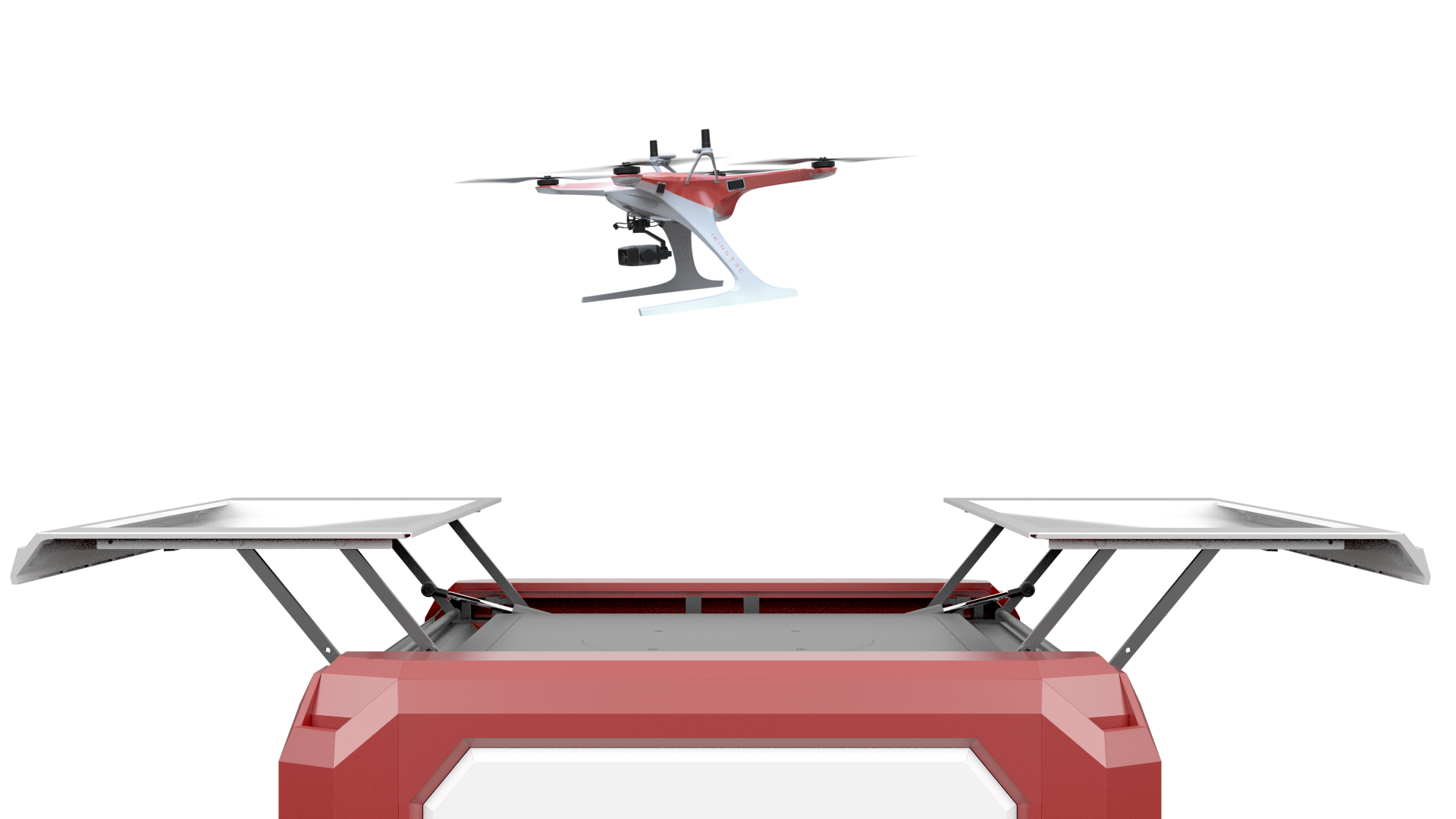

“Orca”

industrial drone

Independently developed by I-KINGTEC. Through using the designing schemes of bionics and aerodynamics, the “Orcas” do not need drone pilots to manipulate during the working process for they can flexibly respond to multi-scene tasks.

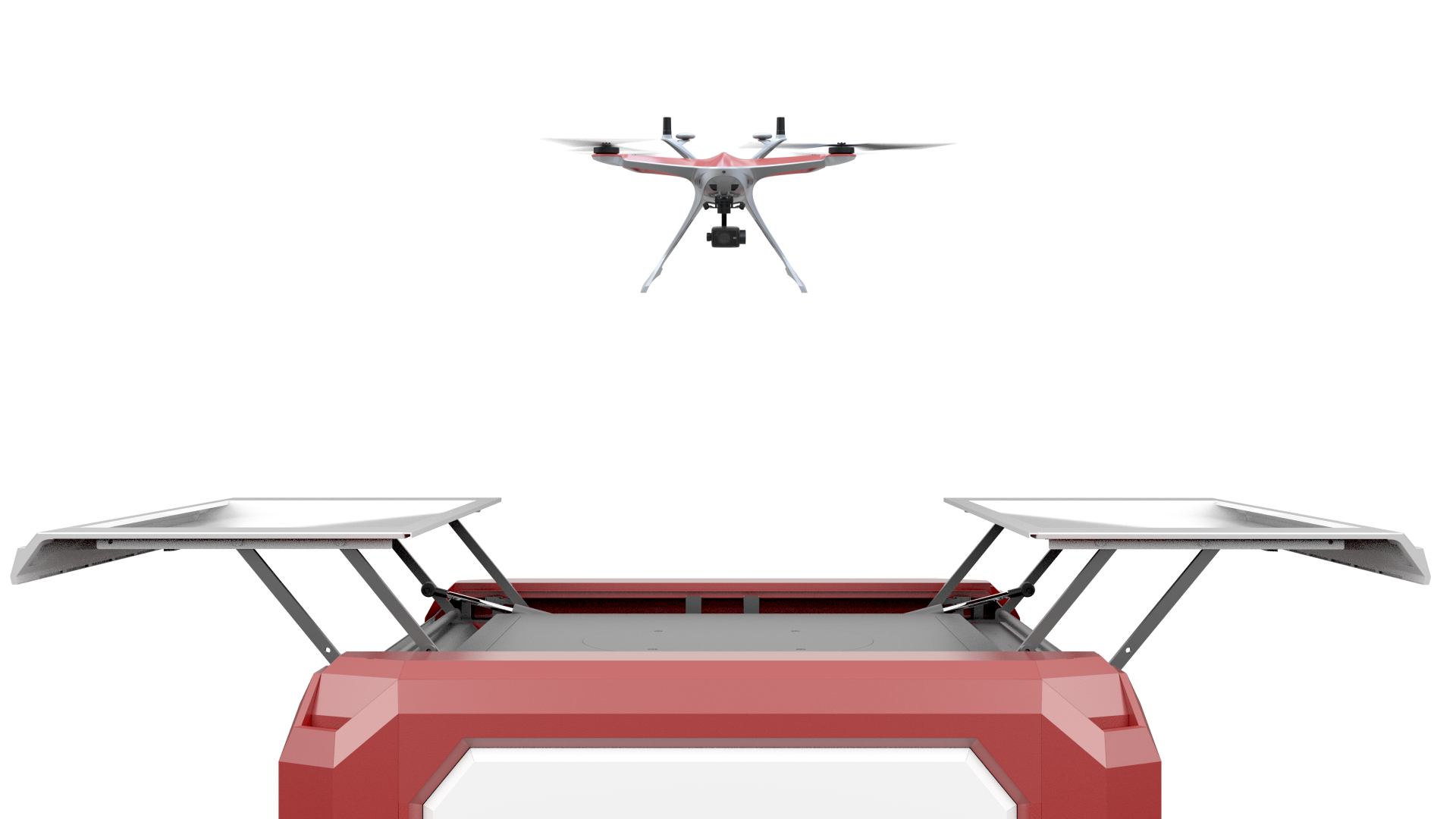

“Orca”

industrial drone

Independently developed by I-KINGTEC. Through using the designing schemes of bionics and aerodynamics, the “Orcas” do not need drone pilots to manipulate during the working process for they can flexibly respond to multi-scene tasks.

Multi-sensor

pod

the capability that the collaborative perception data can be automatically replaced during working, the system becomes powerful in various skills.

30x optical zoom pod

- 30x optical zoom, 60x Photoelectric hybrid zoom

- Picture resolution: 20 million pixels

- Video resolution: 1920X 1080/30 fps

- Stabilization gimbal: three-axis fully self-stabilizing gimbal

- Storage capacity: 128 G

Full frame pod

- Picture pixel: 61 million

- Video resolution: 3840×2160(based on 6k supersampling)

- Lens: 50mm/35mm

- Sensor size :36×24mm

- Anti-shake level: Five-axis anti-shake

Tweeter megaphone pod

- Effective speaker distance: ≥300m

- Sound pressure: ≥100dp

- Working temperature: -10~+40℃

- Communication distance: unlimited

- Protection level: IP43

Laser-image fusion modeling instrument

- Point density: >100/㎡

- Range-measuring accuracy: ±2cm

- Range: 200m/260m

- IMU update rate: 200Hz

- Scanning angle: 360°×30°/38°

Infrared thermal pod

- Temperature range: -20~+600℃

- Resolution: 640+512

- Thermal sensitivity: 60mk@f/1,30°,50Hz

- Precision: Measuring range ±2% or ±2°C

- Detector type: Uncooled vanadium oxide VOx focal plane detector

Laser-image fusion modeling instrument

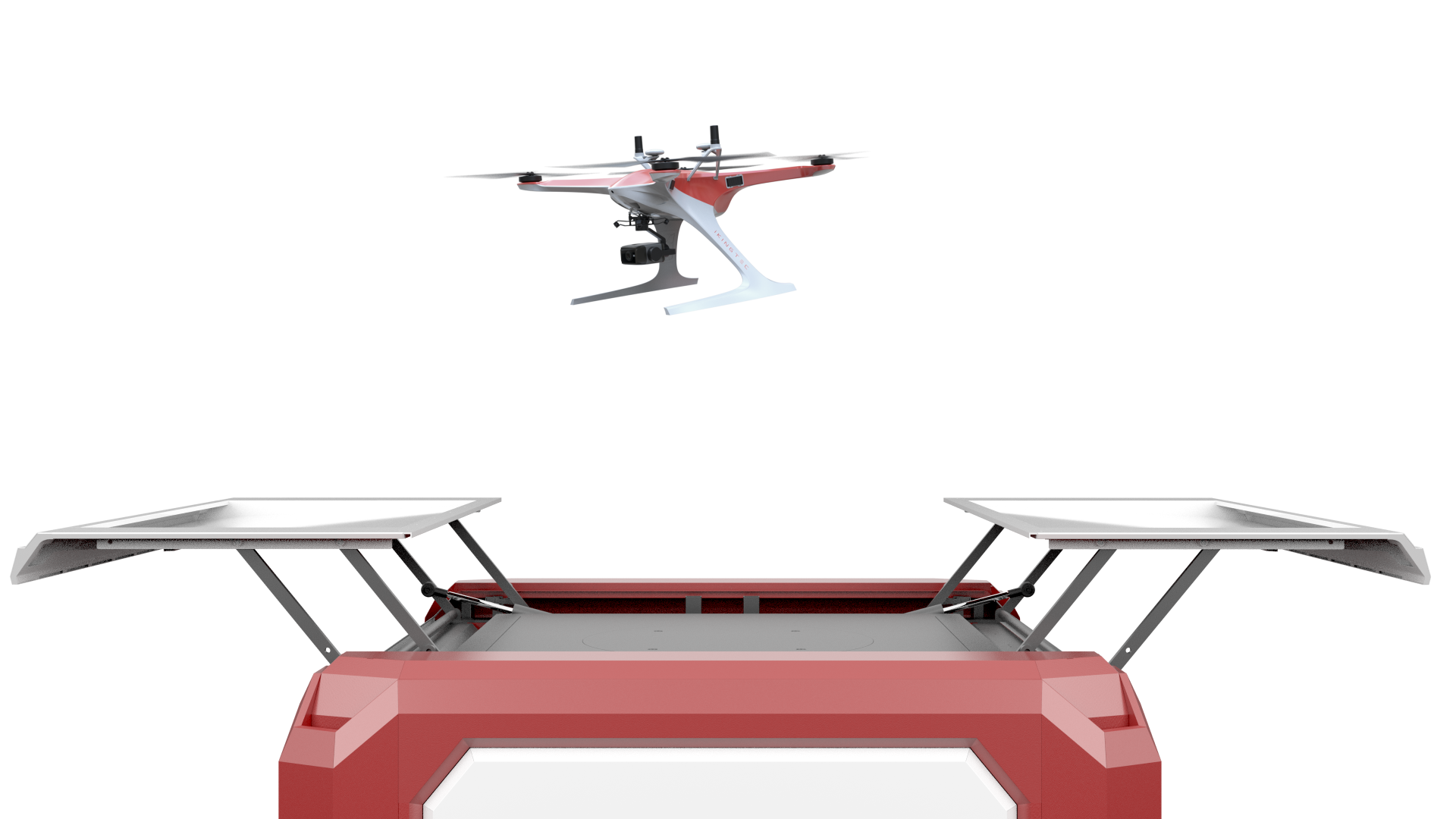

Super flighting performance

The maximum operating time of a single sortie can last up to

![]()

6-kilometer coverage area

Through the effective and autonomous coordination of the fully autonomous drones and the mobile fully automatic airports,

a single product system can achieve a maximum of 8-hour inspecting operation within a 6-kilometer inspection range,

uninterruptedly and independently.

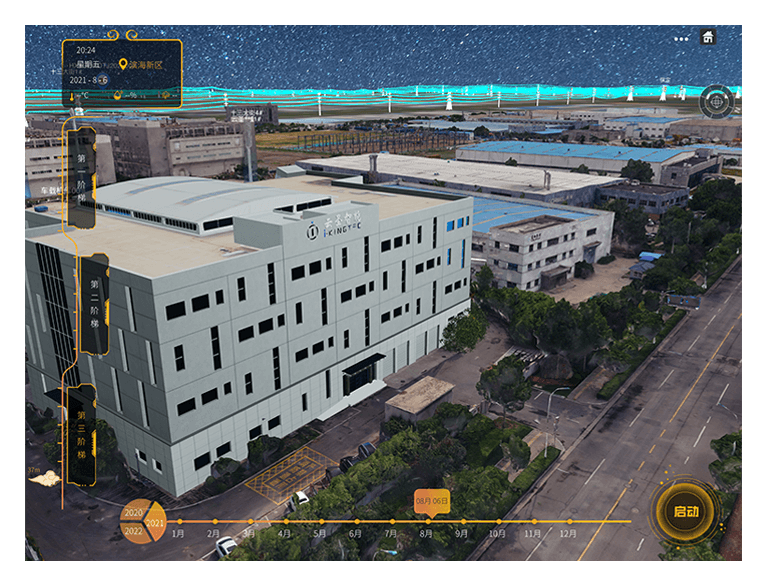

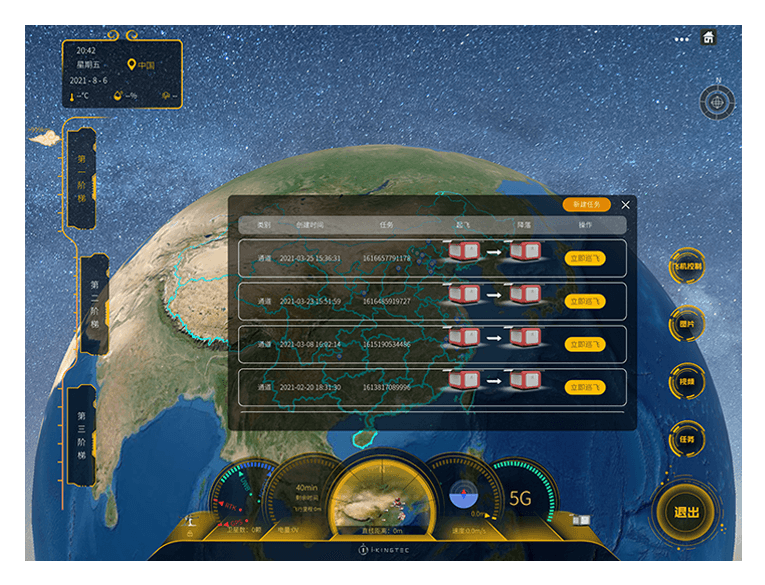

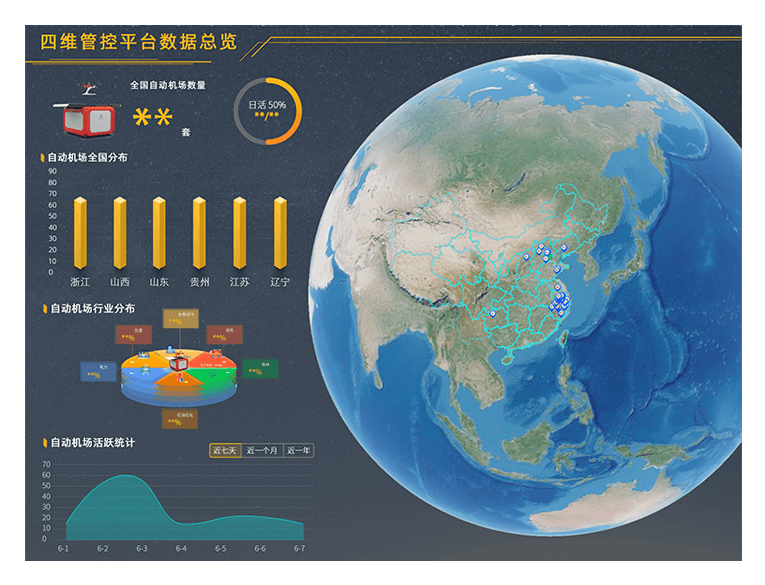

“Tiger vision” four-dimensional holographic control system

The digital twin-type integrated control platform realizes the systematic, intelligent, visual and streamlined management of the industry scene operation.

- Artificial intelligence recognition system

- Digital map management system

- Ultra-low-altitude flight control system

- “Age of Empires” precision scheduling system

- Mind-reading big data analysis system

端边云一体化协同

智能计算

工业无人机边缘端计算能力结合系统平台云计算能力,实现数据从前期标准化采集到 后期智能可视化分析的全流程管理。

“Tiger vision” four-dimensional holographic control system

The digital twin-type integrated control platform realizes the systematic, intelligent, visual and streamlined management of the industry scene operation.

- Artificial intelligence recognition system

- Digital map management system

- Ultra-low-altitude flight control system

- “Age of Empires” precision scheduling system

- Mind-reading big data analysis system

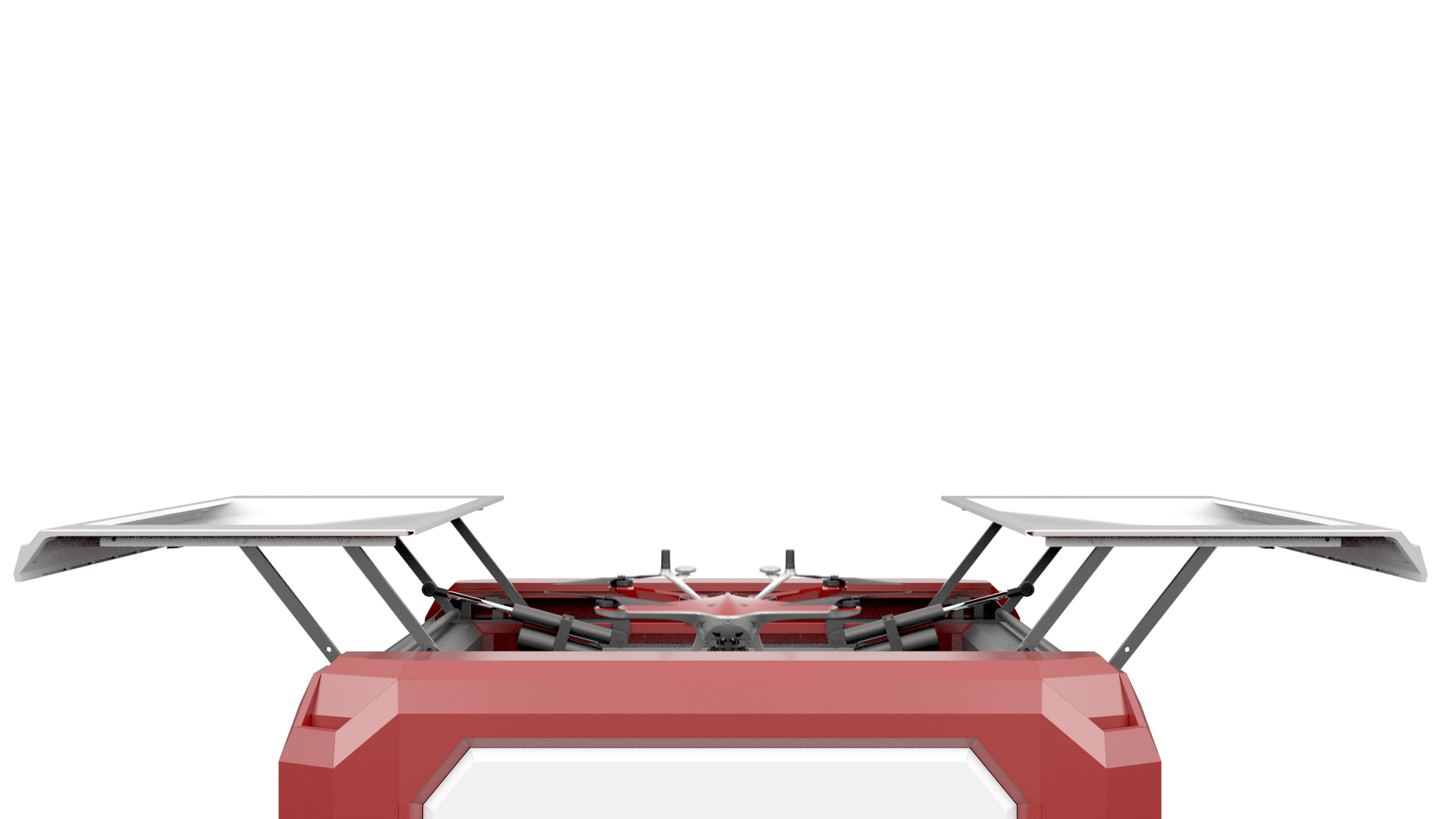

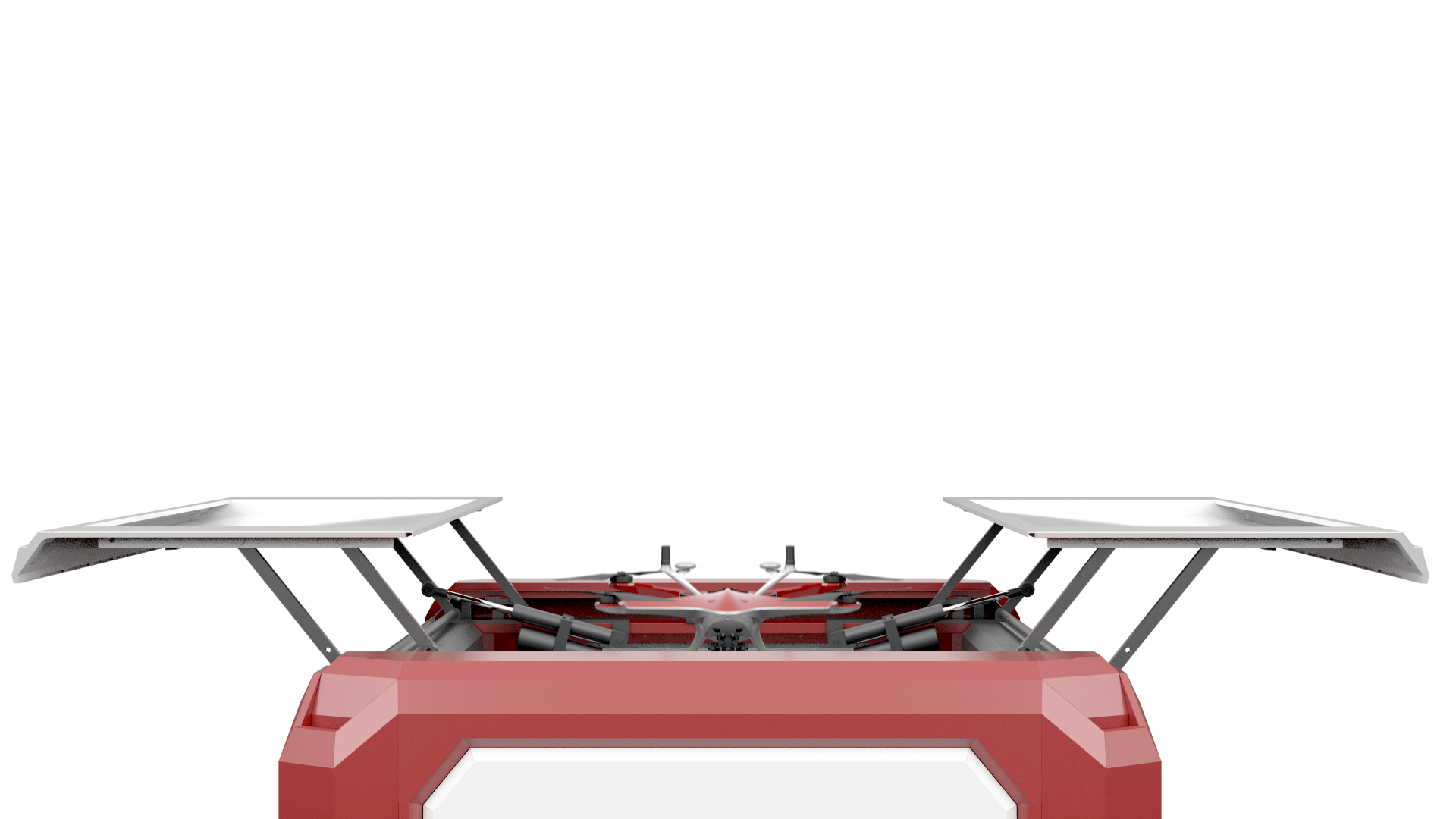

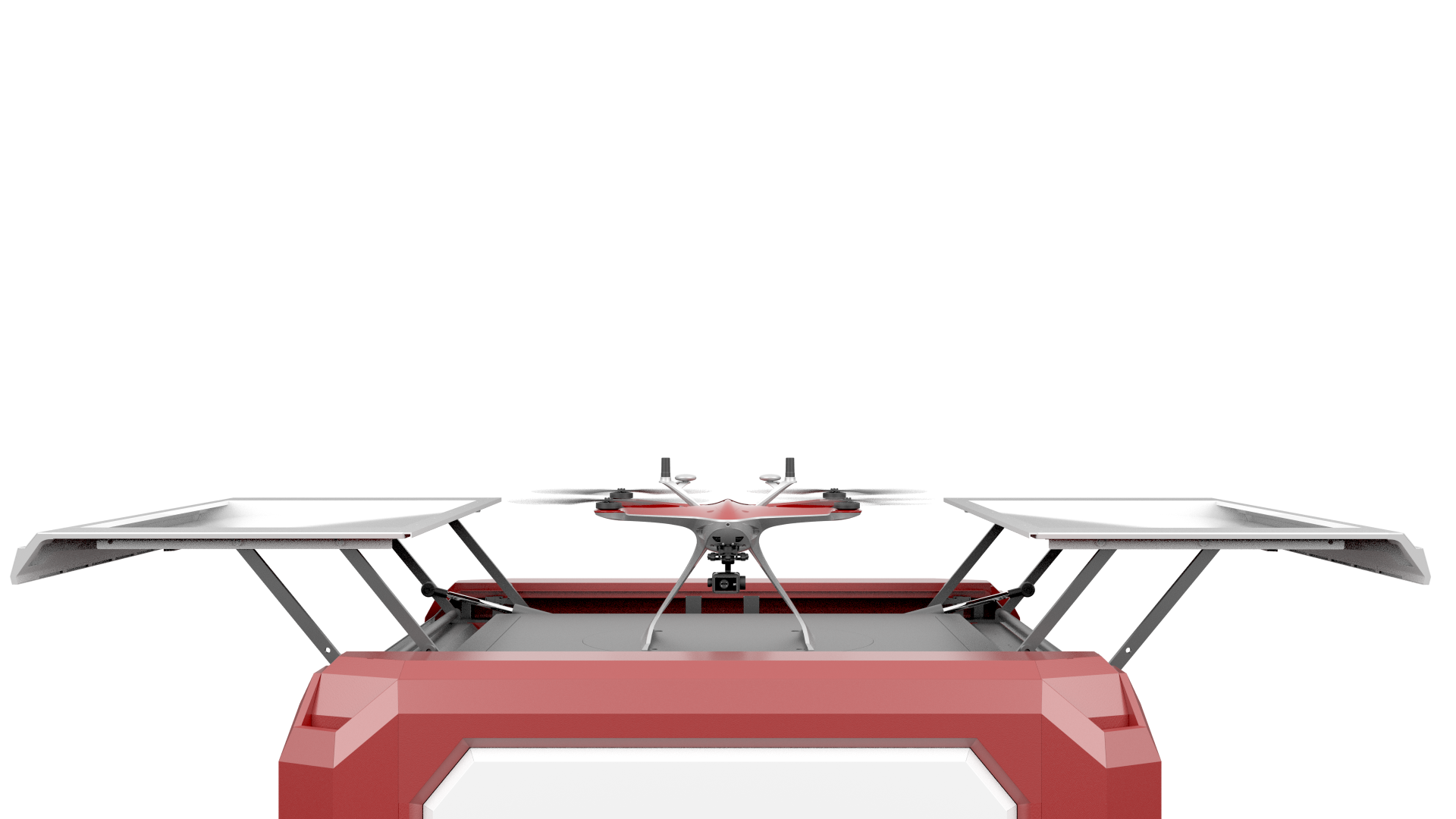

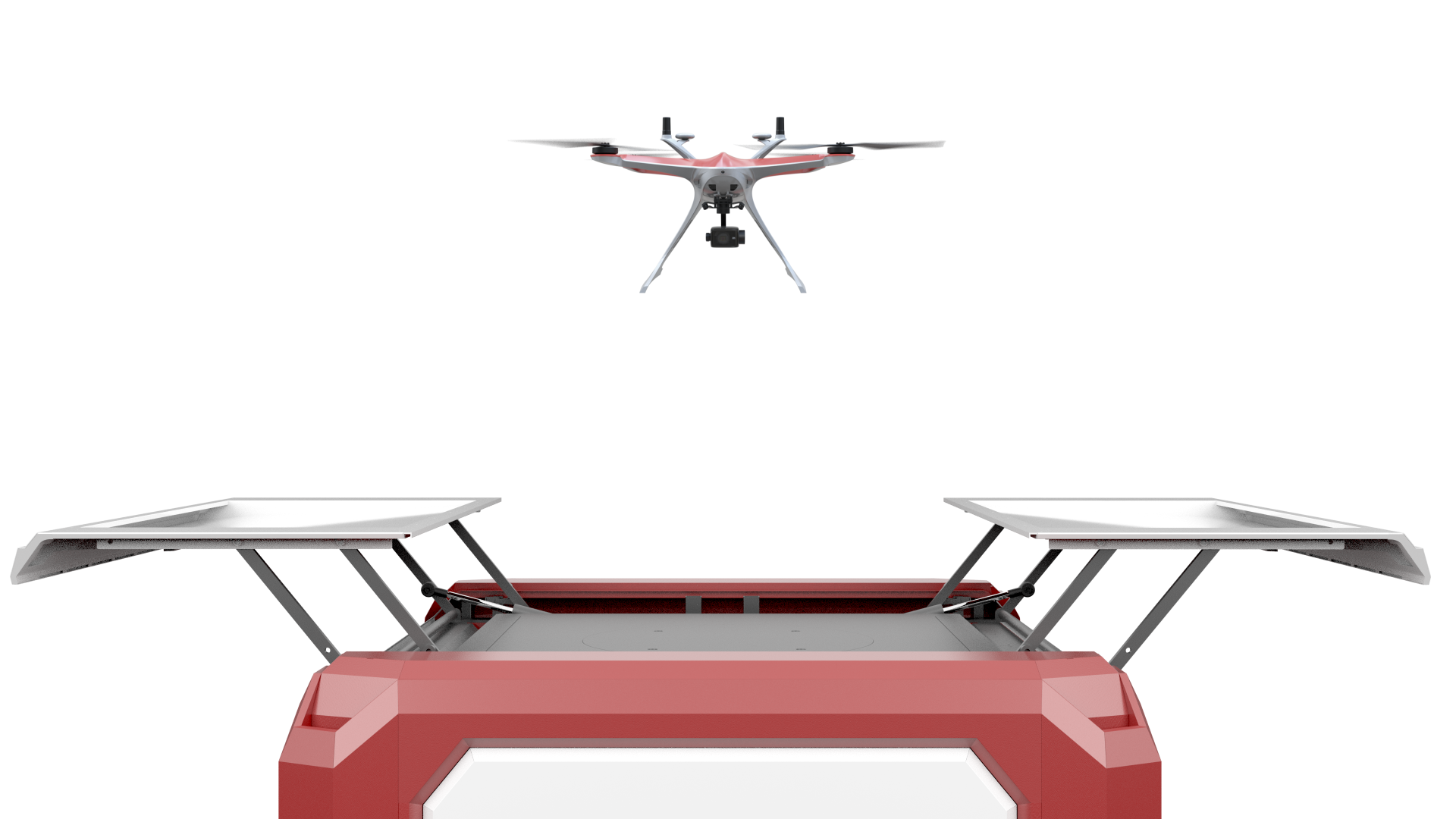

Fully autonomous and precise landing

Use GPS, RTK, UWB, vision and other positioning technologies to ensure that the aircraft can accurately land back to the fixed airport, then change the battery and sensor before taking-off again for the next mission.

“Orca” industrial UAV

“Orca” industrial UAV

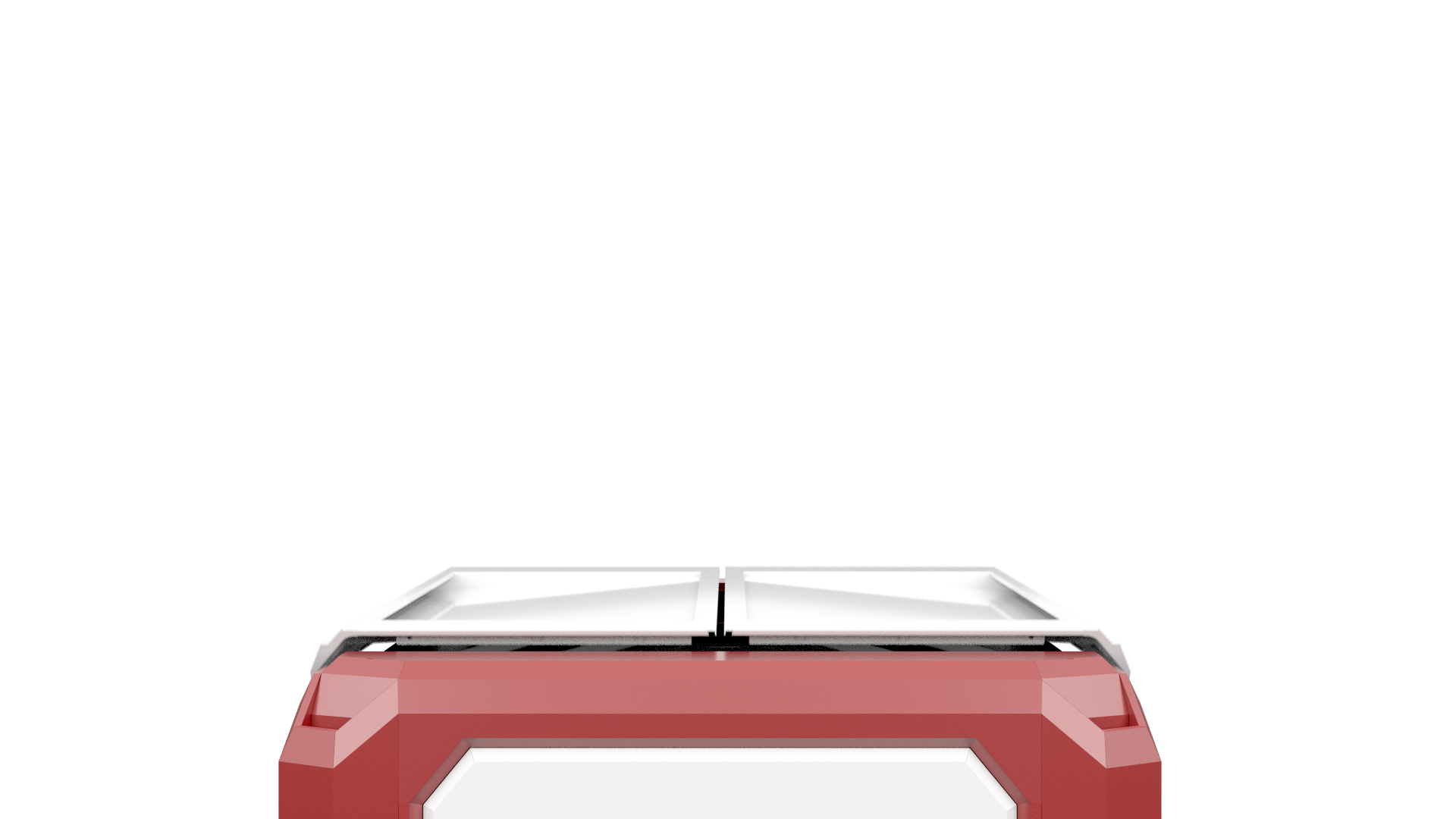

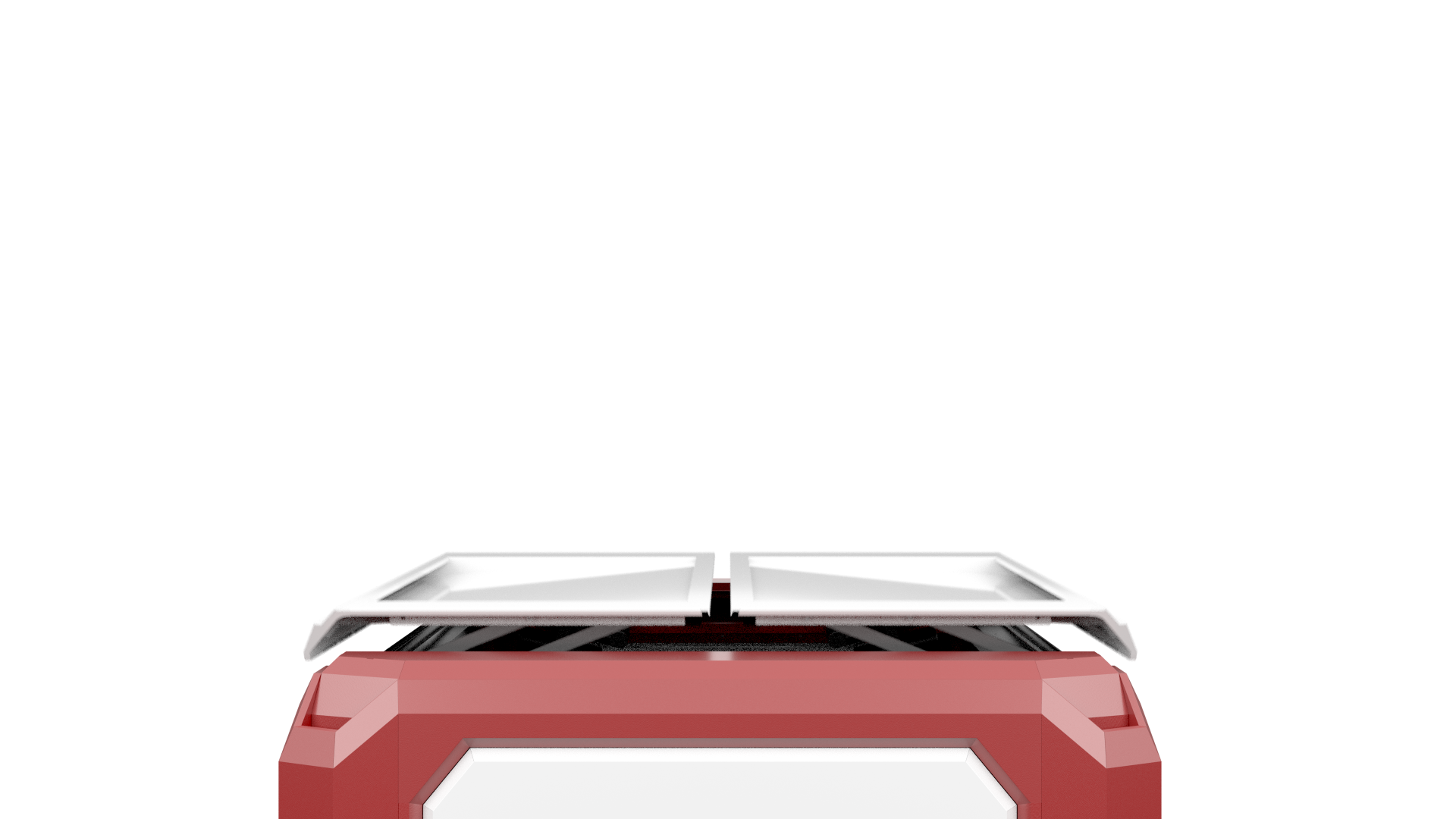

“Tiger Den” fixed fully automated airport

“Tiger Den” fixed fully automated airport

“Tiger vision” four-dimensional holographic control platform

“Tiger vision” four-dimensional holographic control platform